Engineering plastics offer durability, heat resistance, and high impact strength compared to conventional plastics. These properties make them suitable for use in varied applications across industries such as automotive, electrical & electronics, industrial & machinery, consumer goods, and others. In the automotive industry, engineering plastics help reduce the weight of vehicles while maintaining rigidity, improving fuel efficiency. The growing demand for lightweight and durable materials from the automotive sector is expected to drive the growth of the engineering plastics market.

The Global Engineering Plastics Market Demand is estimated to be valued at US$ 150.55 Mn in 2024 and is expected to exhibit a CAGR of 7.2% over the forecast period 2024 to 2031.

Key Takeaways

Key players: Key players operating in the engineering plastics market are Eli Lilly and Company, Sanofi S.A., Cadila Healthcare Limited, Cipla Limited, Castle Biosciences, Regeneron Pharmaceuticals, Inc., Merck & Co., Inc., Vidac Pharma, LEO Pharma A/S, Regeneron Pharmaceuticals, Inc., Merck Sharp & Dohme, and Amgen Inc.

Key opportunities: The growing demand for engineering plastics from end-use industries such as automotive and electronics due to their superior properties is expected to offer lucrative growth opportunities for players in the market.

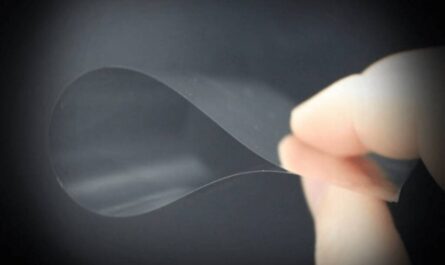

Technological advancements: Leading players are focusing on developing bio-based and recyclable engineering plastics through advanced technologies such as self-healing polymers to reduce environmental footprint and meet sustainability goals.

Market drivers: The increasing use of engineering plastics market in electric vehicles due to their high heat resistance, durability and lightweight properties is a key factor driving the engineering plastics market growth. Stringent regulations regarding vehicle emission levels are also catalyzing automakers to adopt engineering plastics to produce lighter and more fuel-efficient vehicles.

Current challenges in engineering plastics market:

– Volatility in raw material prices affects overall costs of production and profit margins. Fluctuations in crude oil prices poses major challenge.

– Growing concerns regarding environmental impact of plastics usage and disposal. Stringent regulations being implemented for reducing usage of plastics.

– Increasing demand for bio-based and recyclable engineering plastics poses technological challenges in terms of properties and production processes.

SWOT Analysis

Strength: Thermoplastic properties such as moldability, resistance to chemicals and ability to be recycled easily.

Weakness: Higher production costs compared to traditional materials.

Opportunity: Growing end-use applications in automotive, electronics, construction and packaging industries.

Threats: Substitution threat from other competitive materials having better properties.

Geographical regions with high market value currently include Asia Pacific, North America and Europe. Within Asia Pacific, China and India hold major shares owing to vast automotive and electronics manufacturing base.

The Middle East and Africa region is expected to emerge as the fastest growing market for engineering plastics during the forecast period. This can be attributed to ongoing infrastructure development projects and urbanization trends driving demand from construction and automotive sectors across GCC countries.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it