Engineering plastics are widely used in various industrial applications owing to their high strength, rigidity, heat resistance, and durability properties. Some key engineering plastics include polyamide (PA), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyacetal/polyoxymethylene (POM), polysulfone (PSU), and others. These plastics find extensive usage in automotive components, electrical & electronics, consumer goods, industrial & machinery, packaging, and medical devices. In the automotive industry, engineering plastics are utilized to manufacture lightweight components like instrument panels, door panels, bumpers, and various functional parts owing to their corrosion resistance and impact strength. The growing automotive production globally is fueling the demand for engineering plastics.

The global Engineering Plastics Market is estimated to be valued at US$ 130.68 Bn in 2023 and is expected to exhibit a CAGR of 4.5% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market key trends:

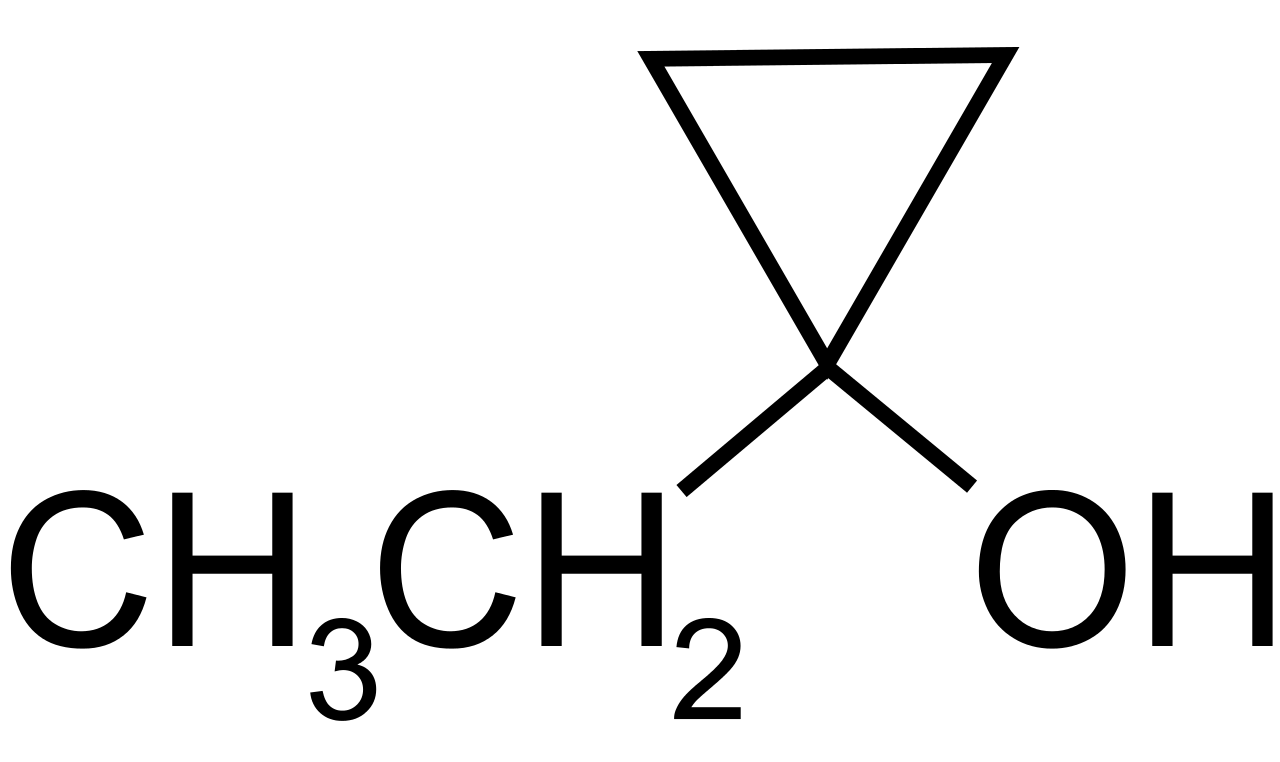

One of the key trends in the engineering plastics market is the growing adoption of bio-based and biodegradable engineering plastics. Conventional petroleum-based plastics have raised significant environmental concerns regarding plastic waste. This has accelerated the adoption of sustainable and eco-friendly bio-based plastics produced from renewable feedstocks like sugarcane, corn starch, cassava roots, and others. Leading players are extensively investing in R&D to develop novel bio-based engineering plastic grades with comparable mechanical and physical properties to traditional plastics. For instance, in 2021, BASF introduced its bio-based polybutylene adipate terephthalate (PBAT) ecomid under its ecoflex brand for compostable and biodegradable applications.

Porter’s Analysis

Threat of new entrants: The engineering plastics market requires high capital investment for R&D and production facilities, acting as a barrier to entry. However, opportunities exist for specialized niche products.

Bargaining power of buyers: Large buyers in end-use industries like automotive and consumer goods have significant bargaining power to negotiate on price and quality standards.

Bargaining power of suppliers: The market has a concentration of major players controlling the supply chain. Suppliers thus have moderate bargaining power.

Threat of new substitutes: New materials face technical and commercial adoption challenges. Established plastics still have advantages over potential substitutes.

Competitive rivalry: The market has global players with broad production bases and regional specialists. Competition is based on product innovation, quality, and pricing.

Key Takeaways

The Global Engineering Plastics Market Size is expected to witness high growth over the forecast period of 2023 to 2030.

Regional analysis: Asia Pacific dominates the market currently and is expected to remain the fastest growing region during the forecast period. This is owing to strong demand from the automotive and electronics industries in China, India, Japan, and South Korea. Europe and North America are also major regional markets driven by automotive manufacturing.

Key players: Key players operating in the engineering plastics market are Kitchen Magic, Rev-A-Shelf, Knape & Vogt Manufacturing Company, Enclume Design Products, Kesseböhmer Clever Storage, ShelfGenie Franchise Systems, LLC, Old Dutch International, Anchor Hocking, LLC, Blum Australia Pty Ltd, Inter IKEA Systems B.V., Flywell International Corp, Masterclass Kitchens, and Others. Major players are focusing on new product development through investments in R&D to strengthen their positions.