Chromium plating has been an important industrial process for decades, employed across many industries for its corrosion resistance and aesthetic properties. However, traditional hexavalent chromium plating methods have come under increased scrutiny due to health and environmental concerns associated with hexavalent chromium contamination. Thankfully, trivalent chromium finishing has emerged as a viable alternative finishing method that addresses these concerns.

What is Trivalent Chromium Finishing?

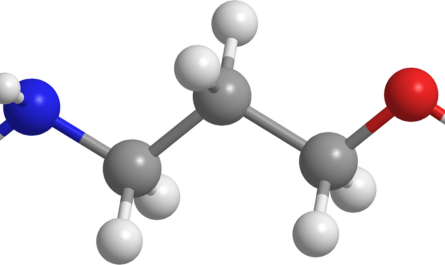

Trivalent chromium finishing, also known as trivalent chromium plating or trivalent chromium deposition, is an electroplating process that utilizes trivalent chromium instead of the traditionally used hexavalent chromium in plating baths. Trivalent chromium, which has a +3 oxidation state compared to hexavalent chromium’s +6 state, is significantly less toxic and carcinogenic than its hexavalent counterpart. The trivalent chromium ions are deposited onto a substrate such as metal alloy through an electrochemical process to provide protective and decorative finishes.

Advantages over Hexavalent Chromium

Trivalent Chromium Finishing offers several advantages over traditional hexavalent chromium plating methods from health, safety, and environmental standpoints.

Health and Safety

– Trivalent chromium is considered a non-carcinogen and much less toxic and irritating than hexavalent chromium. It does not cause respiratory issues like asthmatic bronchitis from hexavalent chromium inhalation.

Environmental Impact

– Wastewater from trivalent chromium plating does not require expensive chromium reduction processes since trivalent chromium is immobile and non-toxic in the environment. This significantly lowers hazardous waste treatment costs.

– Plating sludge from trivalent chromium contains beneficially available chromium that can be recovered and recycled back into the plating process.

Performance

– Properly formulated trivalent chromium coatings provide equivalent corrosion protection, hardness, and wear resistance as hexavalent chromium coatings. Finished parts meet performance requirements.

Regulatory Drivers

– Many countries and states have stringent regulations to curb hexavalent chromium emissions and discharges due to its carcinogenic nature. Trivalent chromium alternatives allow compliance with these environmental norms.

Growing Applications

Driven by the above advantages, trivalent chromium finishing is seeing increasing adoption across various industries as a drop-in replacement for hexavalent chromium plating. Some prominent application areas include:

Aerospace

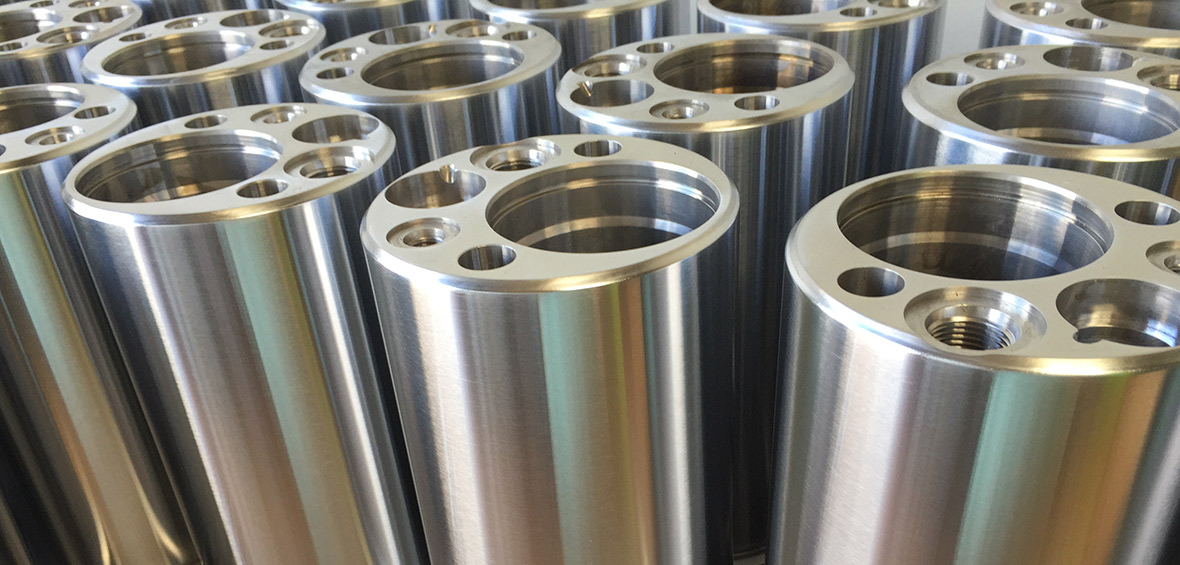

– Leading aircraft and aero-engine OEMs are replacing hexavalent chrome processes for corrosive protection of critical components like landing gears and turbine parts.

Automotive

– Auto giants are employing trivalent chromium for functional and aesthetic chrome plating of wheels, bumpers, and other exterior plastic trim pieces.

Metal Finishing

– Job shops and contract platers are transitioning to trivalent chrome from hexavalent to remain compliant and competitive for metal finishing requirements.

Military and Defence

– Stringent USEPA regulations are driving the switch to non-toxic trivalent alternatives for corrosion protection of firearms, vehicles, and other military hardware.

Issues with Transition

While the overall transition has been positive, some challenges remain with completely replacing hexavalent chromium globally:

– Retooling of plating lines and replacement of existing baths requires significant capital investments which impacts the pace of change for some companies.

– Lack of process standardization as different suppliers have formulated proprietary trivalent plating solutions making full validation and approval cycles long.

– Resistance from a few players still relying on toxic hexavalent technology due to lack of compliance monitoring in developing markets.

trivalent chromium finishing has successfully established itself as an environment-friendly and safer alternative to the traditionally used hexavalent chromium plating. Major industries have acknowledged its merits and are actively pursuing the changeover. With new innovations to further optimize process efficiencies and as regulatory pressure on hexavalent chrome increases worldwide, trivalent chromium finishing is poised to become the dominant chrome plating technology of choice going forward. Its widespread adoption will ensure a more sustainable future for surface finishing processes.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it