However, during the transportation through miles of pipelines, various mineral scale deposits start forming on the inner surface of the pipelines due to the chemical reactions between the transported hydrocarbons and water. These scale deposits gradually build up and clog the pipelines, reducing the flow capacity and increasing pressure drops. To remove these scale deposits and maintain pipeline efficiency, oil and gas companies extensively use chemical descaling solutions known as oil and gas descalers.

Scale Deposit Formation

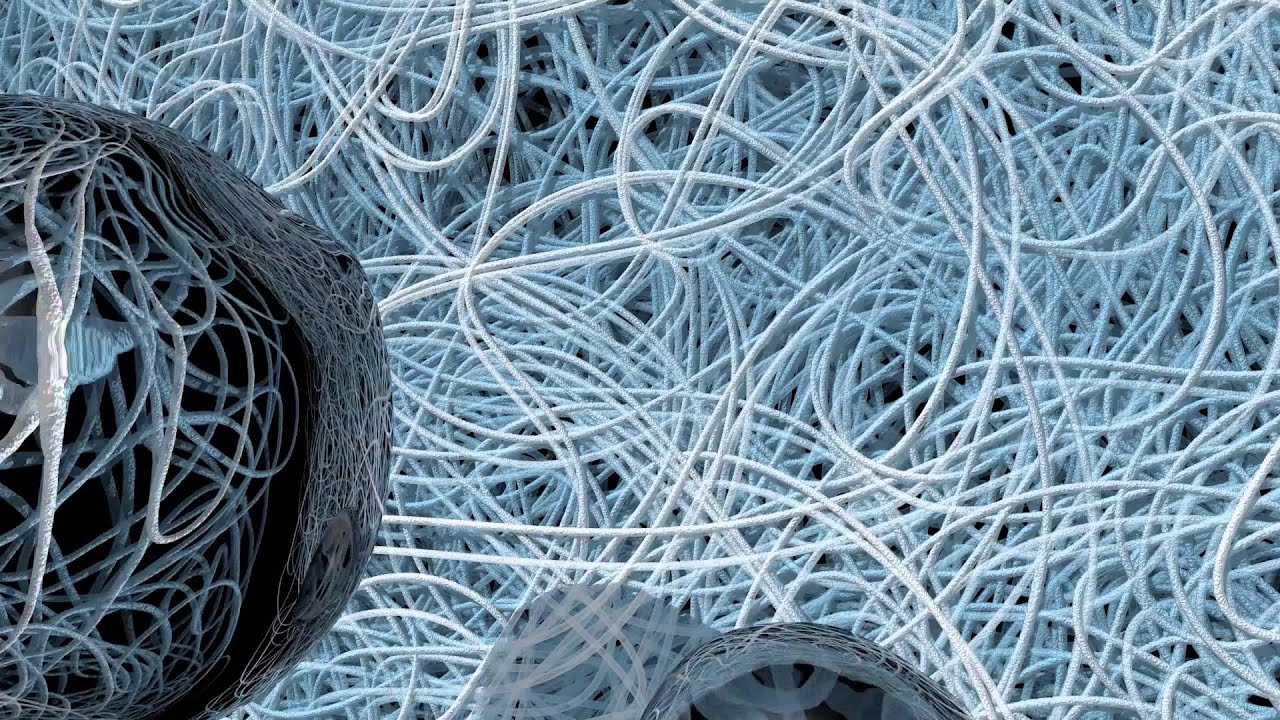

The scale deposits in oil and gas pipelines are mainly composed of calcium carbonate, barium sulfate, strontium sulfate, and iron sulfide. These insoluble mineral scales are formed due to the reaction of hydrocarbons with dissolved calcium, barium, strontium, and sulfate ions present in the formation water that is co-produced with oil and gas. The reaction conditions like temperature, pressure facilitate the precipitation of these scales on the inner surface and along the conduit walls of pipelines. If left unattended, these hard mineral scales can build up over time reducing pipe diameter and restrict hydrocarbon flow.

Impacts of Scale Deposits

The accumulation of scale deposits in the pipelines leads to many operational issues for oil and gas industry:

– Reduced Throughput: As scale deposits coat the inner pipe wall surface, it decreases the internal diameter of the pipe. This decreases the cross-sectional area available for flow resulting in reduced throughput capacity. For example, a 1/16 inches thick scale deposit can reduce pipeline capacity by 10%.

– Increased Pressure Drop: The scale buildup causes an increase in friction between the flowing fluid and pipe wall. This leads to a rise in static pressure and pressure drop between the inlet and outlet of pipelines. More energy is required to maintain the same flowrate.

– Flow Restrictions: Thick hard scales can completely restrict the flow in sections of the pipeline if prompt actions are not taken. This needs sectional cleaning and removal of restriction.

– Corrosion Under the Scale: The microorganisms and corrosive agents get trapped under the scale layers and cause localized corrosion like pitting under scales. This weakens the pipe strength over time.

– Equipment Damage: Thick restrictions in pipelines can damage pumps and equipment by running dry or due to increased discharge pressures. This leads to loss of production and higher maintenance costs.

– Loss of Production: All the issues above collectively reduce the transport capacity and cause production shutdowns for cleaning and maintenance. This directly impacts the profitability.

Role of Oil and Gas Descalers

To address the scale deposition problems, oil and gas producers rely on chemical descaling solutions called oil and gas descalers. These are specifically formulated chemical blends that have excellent scale dissolving abilities. Oil and Gas Descaler work on dissolved scale present in pipelines and also loosen the already deposited scales for easy flushing out.

Mechanism of Descaling:

Oil and gas descalers work through these mechanisms:

– Chelation – The chelating agents form soluble chelates by complexing with metal ions like calcium and barium present in scales. This prevents further scale formation.

– Sequestration – Other ingredients sequester the metal cations and keep them suspended in solution avoiding re-precipitation of dissolved scales.

– Solubilization – Acids and buffers present help dissolve existing mineral scales by reducing their solubility.

– Dispersancy – Surfactants and dispersants break chunks of scales into smaller particles that can be removed easily from pipes.

Typically descaling treatment involves circulating the chemical solution throughout the pipeline system using pig launchers and receivers. The solution dwell time depends on extent of scaling. Gradually scales dissolve and get removed as dissolved minerals or loose particles in the following water flush.

Types of Descalers

Descalers for various application areas have been developed based on the type of scales to be removed:

– Crude Oil Pipelines: Removes calcium carbonate, barium sulfate and iron sulfide scales.

– Produced Water Systems: Effective on calcium scales and sulfides in separation equipment.

– Sour Gas Systems: Removes hydrogen sulfide induced iron sulfide and scale buildup.

– Offshore Platforms: Descalers suitable for marine discharge and ocean dumping regulations.

– Well Bores and Completions: Dissolves formation damage scales during well intervention operations.

Thus pipeline descaling is essential for all oil and gas infrastructure to sustain smooth and efficient operations by preventing production losses due to scales. Regular maintenance with reliable descaling chemicals ensures long term integrity and profitability.

In summary, scale deposits seriously impact the operational efficiency of oil and gas pipelines. Effective removal and prevention of further scaling is important to uphold the production capacity, lower operating costs and reduce shutdowns. Chemical descaling solutions have become a crucial cog in the wheel for pipeline integrity management programs of oil and gas companies worldwide. Choosing the right type of oil and gas descaler formulated for specific application ensures long lasting protection of assets from scales.

Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it