Automated Liquid Handling Systems:

Automated liquid handling systems have revolutionized laboratory operations by automating tedious and repetitive manual tasks like pipetting, dispensing, mixing liquids and transferring samples. These systems help streamline workflows, improve consistency and accuracy of experimental results and free up lab technicians to focus on more complex assignments. Laboratory automation is no longer a luxury but a necessity to handle the increased workloads of modern life science research and clinical testing.

The Rise of Automation

Automation began entering life science laboratories in the 1980s with the introduction of basic desktop liquid handlers that could dispense predefined volumes of liquids into multi-well plates. These early systems improved throughput and minimized manual errors compared to traditional pipetting. Through the 90s and 2000s, liquid handling automation rapidly advanced as new technologies emerged. Systems became more sophisticated with multi-arm robots, non-contact dispensing techniques and integrated liquid handling and detection modules. Numerous applications like genomics, proteomics and high-throughput screening now rely heavily on automation to process thousands of samples daily.

Key Components of Modern Systems

Modern automated liquid handling systems consist of several core components:

– Liquid handlers: The liquid dispensing component with programsmable pipetting heads and high-precision syringe pumps for aspirating and dispensing attoliter to milliliter volumes.

– Deck/platform: A sturdy mechanism with slots to securely hold labware like plates, tubes, reservoirs during processing. Decks are programmable to move labware between workstations.

– Workstations: Modules integrated on the platform that enable functionalities like liquid transfer, mixing, incubation, detection etc. Common stations include dispensing heads, shaking, heating/cooling modules, plate sealers and readers.

– Control software: Intuitive programming interfaces to design experimental protocols, control system operations, track sample histories and integrate with other lab equipment and databases.

– Connectivity: Interfaces like LIMS connectivity, barcode/RFID readers to import/export sample details, maintain traceability in high-throughput settings.

Key Benefits of Automated Liquid Handling Systems

Faster Processing: Automated liquid handlers can complete multi-step protocols much faster than manual methods. Speeds vary from tens to thousands of samples processed per hour.

Precision and Accuracy: Advanced liquid sensors and controlled dispensing techniques ensure volumes are dispensed to sub-microliter levels with Cv (coefficient of variation) below 5%. Precision improves reproducibility.

Minimized Errors: Machines don’t get bored, distracted or tired. Automation eliminates repetitive stress injuries and reduces human errors from factors like fatigue, improper technique that plague manual methods.

Standardization: Integrated hardware-software systems enable experiments to be repeated identically. Standard operating procedures can be programmed into methods for consistent execution.

Increased Productivity: Automation frees scientists from manual tasks to focus on more complex work like data analysis. It also supports 24/7 operation for continuous processing.

traceability: Connectivity to informatics tools like LIMS enables electronic record-keeping for traceability/compliance in regulated settings like drug discovery and clinical testing.

Types of Automated Systems

Automated liquid handling systems are available in different categories based on throughput needs –

Desktop Systems: Designed for basic to moderate throughput of up to a few hundred samples/assays per run. Typical deck sizes hold 40-384 well plates. Suited for teaching/core labs.

Medium / High Throughput Systems: Deck sizes support 1536 well plates for high density assay plates. Hundreds to thousands of samples can be processed per run. Used in drug discovery, genomics labs requiring medium-high sample volumes.

Very High Throughput Systems: Deck sizes support 1536-3456 well plates. Robotic mechanisms enable fully automated processing of 15000-45000 samples in a day. Used in contract research and clinical testing organizations with enormous daily workloads.

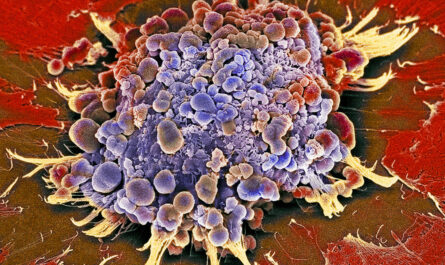

Aseptic/Biocontainment systems: Equipped with isolators, airlocks and specialized handling tools to work with biological hazards like viruses and bacteria without compromising biosecurity.

In addition, specialized automation exists for areas like in-vivo cell cultures, live-cell fluidic processing and others. The selection of system type depends on throughput demands and sample characteristics.

Implementation and Challenges

Transitioning to automation involves careful planning to choose appropriate systems, train staff, validate equipment and update facilities if needed. Common challenges include high initial investment, designing optimal protocols, ongoing calibration and maintenance costs. However, a well-managed automation strategy more than recovers costs over the long term through improved productivity and reduced operational expenses.

Overall, automated liquid handling is essential for labs seeking high sample throughput, precision and standardized reproducible results. When combined with intelligent informatics and software platforms, they are becoming powerful tools driving data-intensive fields such as personalized medicine, chemical synthesis and biomolecular analysis. The future of life science research relies on continued evolution of automation technologies.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it