The production and use of 1,3-propanediol or PDO is experiencing significant growth on a global scale. This versatile chemical building block is finding widespread applications in industry that are driving demand higher. In this article, we will explore the expanding market for 1,3-PDO and analyze growth projections.

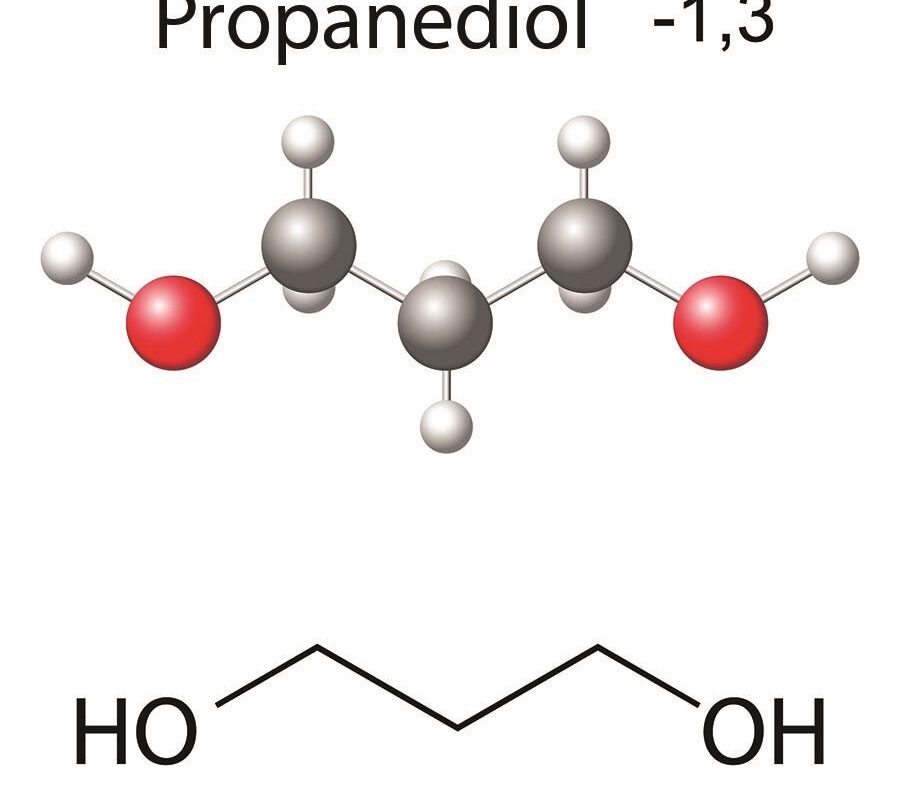

1,3-Propanediol, also known simply as propanediol, is an organic compound with chemical formula C3H8O2. It is a colorless, viscous liquid that is miscible with water and many organic solvents. PDO is produced commercially via fermentation using genetically engineered bacteria that convert renewable feedstocks like corn or sugarcane into the desired product. Its primary uses currently are in the production of polytrimethylene terephthalate (PTT), an engineered plastic, as well as polyurethanes for carpet and textiles.

Rising Production Capacity

Global capacity for manufacturing 1,3-PDO has been expanding significantly as producers work to meet the rapidly growing demand. Major players like DuPont Tate & Lyle Bio Products and Genomatica have announced numerous capacity expansion projects over the past five years. DuPont alone has doubled its capacity to over 300 million pounds annually between facilities in Italy, Tennessee, and Indonesia. New entrants to PDO production using innovative fermentation methods include Corbion and Global BioChem. It is projected that global capacity could reach over 1.5 billion pounds by 2025 according to industry analysts.

Soaring Demand in PTT Production

One of the primary drivers of increased PDO usage has been its role as a raw material in the manufacture of polytrimethylene terephthalate or PTT. This engineered plastic has proven superior properties for textiles like carpet fiber that appeal to brands seeking more sustainable alternatives to nylon. PTT production has been rising at a double-digit pace annually with much of the growth occurring in China and other Asian markets. Leading PTT producers like Shell Chemical and China Petroleum & Chemical Corp continue expanding their capacity and off-take agreements with PDO suppliers. It is expected that PTT will account for over 60% of global PDO demand by 2025.

Other Industrial Applications

While PTT remains its predominant application, 1,3 Propanediol is also finding expanding use in other industrial sectors. Some newer areas of growth include polyurethanes and performance polymers. Specifically, PDO-based polyurethanes are gaining traction for carpet backing, textile coatings, and spandex fibers due to their high elasticity and moisture resistance. It is also being investigated as a bio-based replacement for petrochemical-derived components in polybutylene terephthalate (PBT) resins and thermoplastic elastomers. As a green aliphatic diol, PDO also offers advantages over traditional diols when used as a solvent or in cleaning products and cosmetic formulations.

Sustainability Advantages

An important attribute driving the long-term prospects of 1,3-PDO is its sustainability profile relative to traditional commodity chemicals. As it can be manufactured from renewable non-food plant feedstocks using fermentation, PDO offers a lower greenhouse gas footprint versus fossil fuel-derived alternatives. Its use in products like PTT also enables brands to market more sustainable textiles, replacing petrochemical-based fibers like nylon. Efforts are ongoing to develop fully bio-based PBT and polyurethanes using 1,3-PDO to realize even greatercircularity. Considering rising societal priorities around sustainability, this positionsthe PDO market for continued advancement aligned with global decarbonization goals.

1,3-propanediol has emerged as an increasingly important industrial platform chemical powered by its diverse applications and sustainability advantages over fossil alternatives. Driven by the rising production and consumption of downstream materials like PTT and PBT, demand for PDO is experiencing double-digit annual growth on a global scale according to all available projections. Major players are pouring billions into expanding manufacturing capacity to take advantage of this profitable trend. Looking ahead, ongoing advancements in bio-based chemicals and plastics innovation ensure ongoing opportunities for growth will continue fueling the rise of 1,3-propanediol in industry worldwide.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it