Thermal printing is a digital printing technique that is revolutionizing the way we print receipts, labels, tickets and documents. Using special heat-sensitive paper and ribbon, thermal printers are able to print high-quality text and images without using any ink. Over the past few decades, thermal printing has vastly improved and is now used across various industries due to its reliability, affordability and environment-friendly nature.

History of Thermal Printing

The foundations of Thermal Printing technology were laid in the 1950s when researchers discovered that certain materials changed color irreversibly when heated. In the 1970s, engineers utilized this phenomenon to invent thermal paper, which darkens when heat is applied. The commercial success of thermal paper enabled the development of the first thermal printers in the early 1980s. These early printers were slow and printed only text. However, substantial improvements were made in print speed and print quality over the subsequent decades. By 2000, thermal printing had become the dominant printing technology for receipts, tickets, labels and document on demand applications.

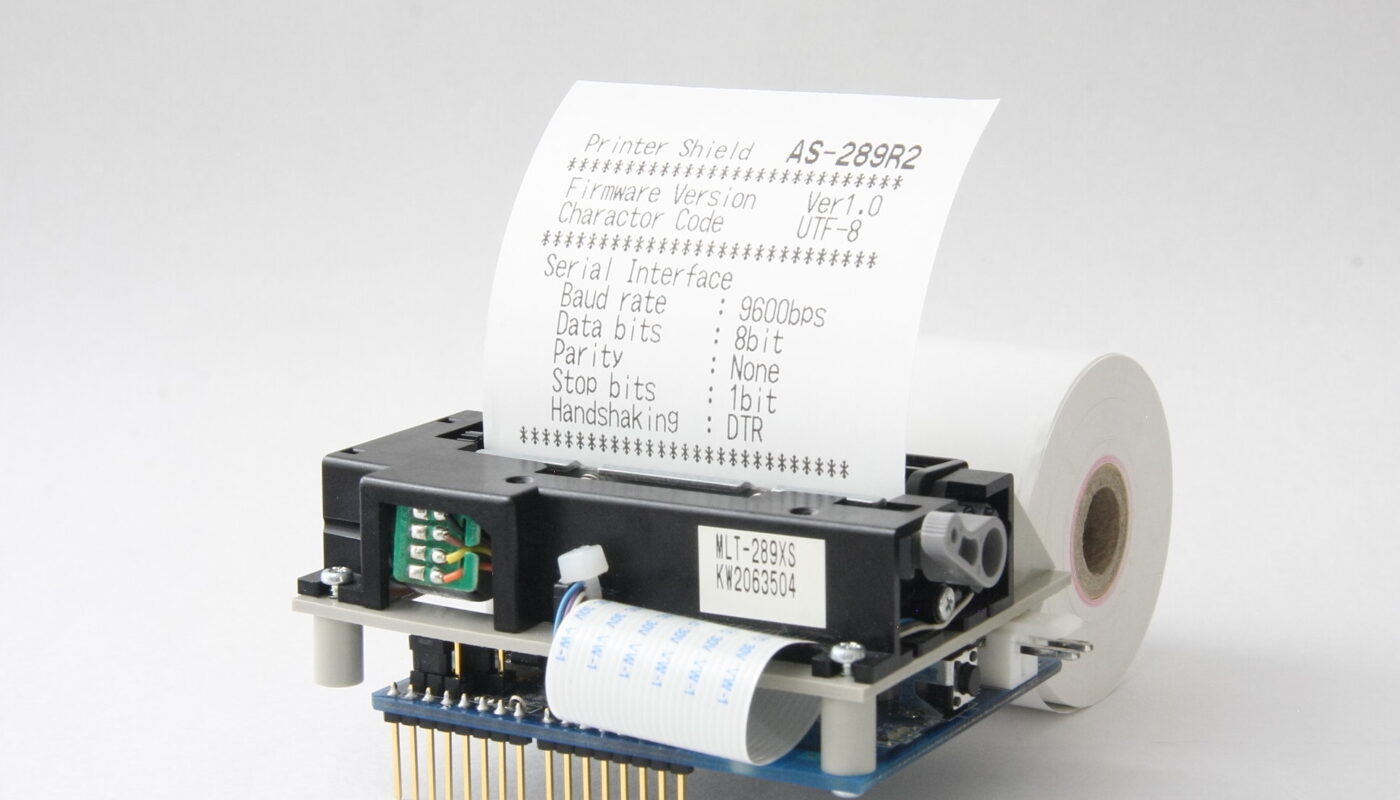

How Thermal Printing Works

Thermal printing relies on a simple and ingenious mechanism. Thermal paper contains heat-sensitive coating layers that change color with heat application. The thermal print head contains several tiny heated elements which are selectively heated by electric current to apply heat image-wise onto the thermal paper. Where heat is applied, the coating changes its color, thus producing text and images. No ink is needed as the color change is a result of a chemical reaction induced by heat. Thermal transfer ribbons are also available which transfer the image onto other substrates like cardstock and plastics.

Key Advantages of Thermal Printing

Inkless Printing: One of the biggest advantages of thermal printing is that it does not require any ink. The image is generated by applying heat directly onto the thermal paper. This makes thermal printing more economical as it eliminates the need to purchase, replace or refill ink cartridges or ribbons.

Reliability: Thermal print heads last several miles of printing unlike inkjet or dot matrix print heads which may require frequent replacement. Thermal printing mechanism is also very robust and capable of standing up to millions of on/off cycles.

Affordability: Overall costs of thermal printers, paper and ribbons are much lower compared to inkjet or laser printers. Thermal printers are also very compact, light and portable making them ideal for mobile applications.

Environment-friendly: Thermal printing is greener technology as it produces no ink waste. Used thermal paper can also be recycled. This makes thermal printing an eco-friendly alternative to ink-based printers.

Applications of Thermal Printing

Point of Sale Receipts: Thermal receipt printers dominate the POS market with over 90% market share worldwide. Benefits like instant printing, portability and reliability make them ideal for retail transactions.

Lottery & Gaming Tickets: Thermal printers are extensively used by state lottery departments and casinos to print millions of tickets every day due to their high-speed capabilities.

Labels & Tags: Various industries use thermal transfer printers to apply tracking labels, price tags, shipping labels and barcode labels onto products or packages at very high speeds.

Airline & Railway Tickets: Most airline companies, railway stations and bus depots rely on networked thermal printers installed at ticket counters to print tickets on the spot.

Document on Demand: Many corporate environments use thermal printers connected to multifunction devices to print documents, forms, invoices only when needed without wasting paper.

Event & Park Ticketing: Organizers of concerts, plays, conferences, amusement parks and fairs use portable thermal printers to issue tickets to visitors on location.

Advancements in Thermal Printing Technology

Higher Resolution Printing: Newer thermal print heads support resolutions up to 300 or even 600 dpi enabling photo-quality printing of graphics, barcodes and signatures.

Faster Print Speeds: Current generation thermal printers are capable of printing 200mm/sec or more. High-speed industrial printers can print over 1000 pages per minute.

Colored Printing: Advances in thermal paper and transfer ribbons allow full-color graphics in addition to text. Colored POS and product labels are quite common now.

Specialized Media: Roll labels, self-adhesive paper, synthetic paper, RFID smart labels are some specialty types designed for durable long-term applications.

Network & Cloud Printing: Modern printers support WiFi, Ethernet, Bluetooth etc. to print from anywhere. Cloud software allows centralized administration of large printers fleets.

Sustainable Options: New eco-friendly formulations in thermal paper use less expensive chemicals. Manufacturers focus on creating recyclable/compostable packaging as well.

The versatility and reliability of thermal printing will ensure its extensive usage well into the future. With ongoing innovations, thermal technology continues to expand into new applications delivering best-in-class printed output economically and sustainably. Thermal printing has indeed revolutionized the paperless printing landscape.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile