The electronics and semiconductor industries have been constantly pushing the boundaries to make chips smaller, faster and more powerful with each new generation. However, shrinking chip components any further using traditional 2D design approaches is becoming increasingly challenging due to physical and technical limitations.

What are 3D Integrated Circuits?

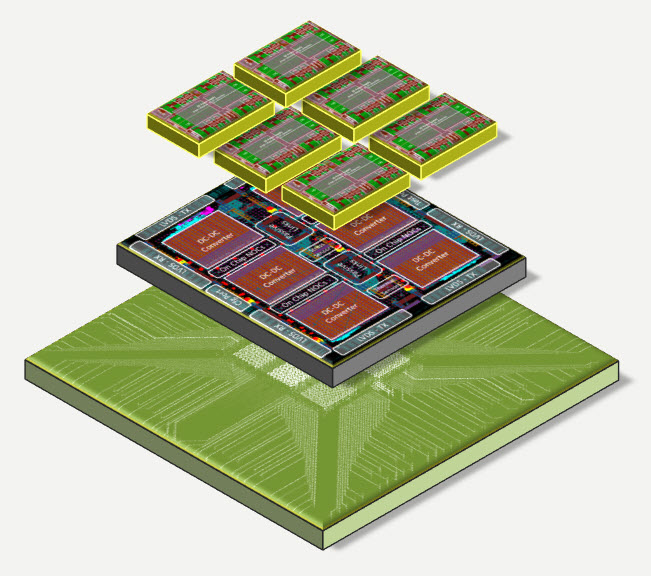

3D ICs refer to stacking layers of active silicon chips and interconnecting them using through-silicon vias (TSVs), resulting in a three dimensional integrated circuit architecture. In a 2D planar chip, different components such as logic, memory, analog, sensor interfaces etc. are arranged side by side on a single silicon wafer. This limits performance improvements as interconnect delays and parasitic resistances increase with component densities. In contrast, 3D ICs provide a vertical dimension by stacking silicon layers and combining different components in a single package, allowing for higher densities, bandwidth and performance.

Advantages of 3D IC Technology

The key advantages of 3D ICs compared to conventional 2D designs include:

– Higher Integration: 3D stacking allows for unprecedented levels of integration by combining different chip components in a single 3D package. This dramatically improves component densities and reduces chip area requirements.

– Shorter Interconnects: Vertically stacking layers reduces interconnect lengths between components compared to planar layouts. This decreases signal propagation delays and resistive-capacitive parasitic effects associated with long interconnects.

– Improved Bandwidth and Speed: Shorter vertical connections in a 3D design can increase bandwidth and speed of data transfer between densely packed components by up to 5-10X compared to 2D layouts. This boosts overall system performance.

– Lower Power Consumption: Shorter interconnects reduce power losses due to parasitic capacitances and resistances. 3D ICs can lower dynamic and static power consumption and improve power efficiency compared to single-die 2D chips.

– Advanced Functionality: The third dimension expands the design space and enables new complex system-on-chip applications by combining different technologies like CMOS, BiCMOS, MEMS, photonics etc. in a single 3D package.

Types of 3D IC Packaging Technologies

Several 3D packaging technologies have emerged that employ different vertical stacking approaches:

– Wire Bonding: Early 3D IC prototypes used wire bonding to interconnect multiple chip tiers. However, wire bonding scaling issues limited advancement of 3D integration with this approach.

– Through-Silicon Vias (TSV): Now the mainstream 3D IC technology, TSVs are micrometer-sized vias or holes that pass completely through a silicon wafer or die, enabling electrical connections between stacked layers. TSVs offer high density interconnections critical for advanced 3D ICs.

– Silicon Interposer: A passive silicon or glass carrier hosts multiple thin die that are vertically stacked and interconnected using TSVs or micro-bumps. Interposers provide ultrahigh I/O densities and shorter wirelengths.

– Chip Stacking: Thin wafers or dies are bonded/stacked on top of each other and connected electrically and mechanically using micro-bumps or metal bonding. Popular stacking techniques are die-to-wafer and wafer-to-wafer approaches.

Applications and Commercialization

After years of research, 3D IC technology is now maturing for high volume manufacturing. Early adopters include memory vendors leveraging 3D architectures for dense DRAM and NAND devices. Smartphone giants are utilizing advanced 3D packaged designs for application processors and image sensors. 3D ICs are also gaining traction in other areas:

– Graphics/GPUs: 3D stacking is enabling power-efficient, high bandwidth designs for integrated graphics/GPUs in computers, game consoles and augmented reality devices.

– AI Chips: Dense 3D integration of processing cores, memory and analog circuits is critical for next-gen AI/neural network accelerators and edge inference chips.

– High Performance Computing: 3D packages combine logic, memory and photonics in servers and supercomputers to meet demands of exascale computing.

– Automotive Electronics: Advanced 3D SiPs are making inroads into driver assistance, infotainment and autonomous driving platforms for their thermal resilience, miniaturization and reliability.

Challenges and Future Outlook

While 3D integration promises unprecedented levels of performance, several technological hurdles like through-silicon via formation, thermal management, yield and design challenges must still be overcome before 3D ICs can reach their full potential. Manufacturers are continuously working to drive improvements in TSV fabrication yield and reduce TSV defect density. 3D-aware EDA tools are also evolving to tackle thermal, electrical and mechanical issues early in design cycles.

Looking ahead, 3D stacking combined with emerging technologies like integrated photonics, carbon nanotubes and 2.5D/3D packaging is poised to revolutionize manufacturing and accelerate commercial adoption of artificial intelligence, autonomous systems as well as exascale high performance computing over the next decade. 3D integration is undoubtedly shaping up to be a disruptive force that will define the future of semiconductor industry. With continued R&D investments and yield learning, 3D ICs are expected to replace 2D chips as the mainstream chip architecture beyond Moore’s Law.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it