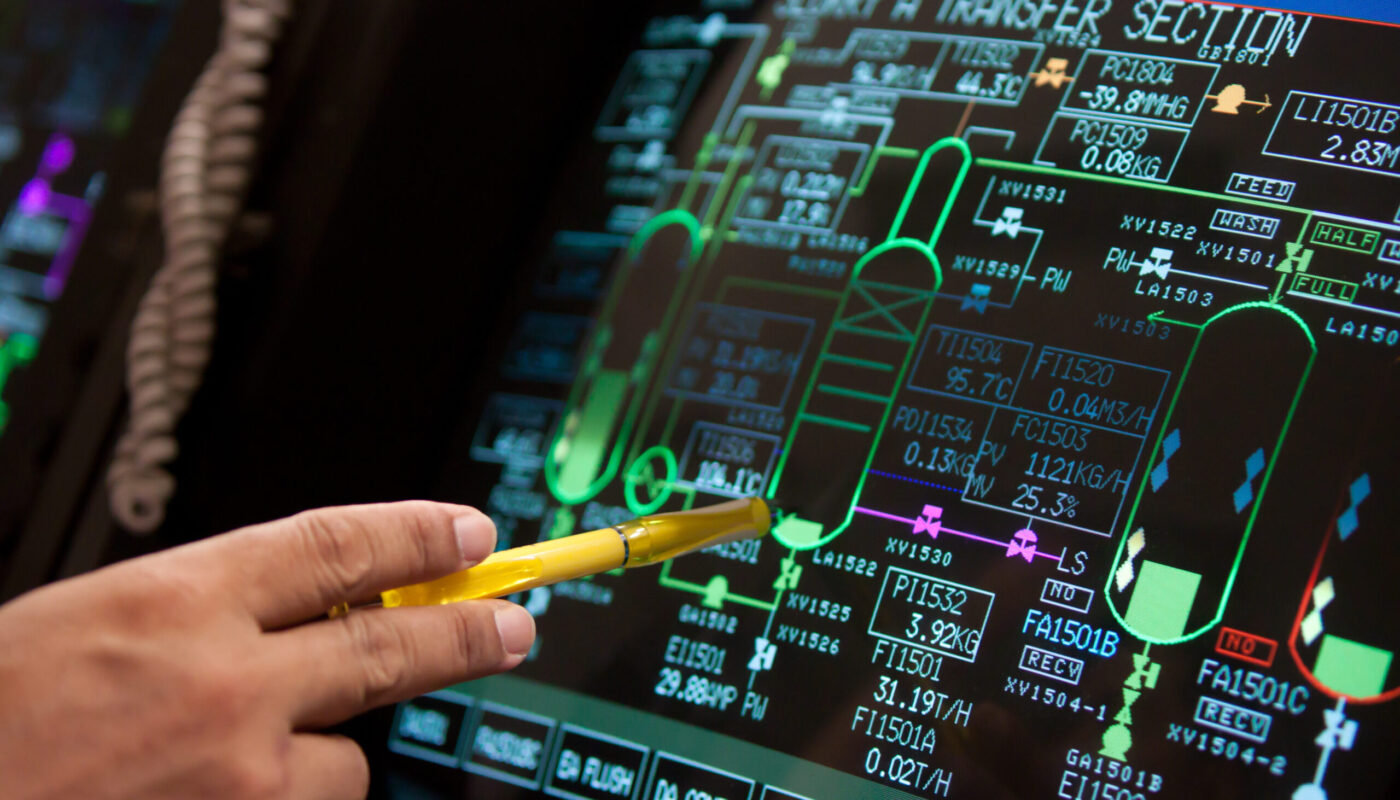

The Industrial Automation and Control Systems Market consist of a variety of programmable logic controllers (PLC), supervisory control and data acquisition systems (SCADA) and industrial robots. These systems help in automating critical manufacturing and industrial processes. The advantages of automation systems include higher productivity, reduced human errors, improved consistency and quality of products. With the growing need for precision, speed and efficiency in production lines across industries like automotive, electronics, food & beverages and oil & gas, the demand for automation control systems has increased substantially.

The Global Industrial Automation and Control Systems Market is estimated to be valued at US$ 201.06 Mn in 2024 and is expected to exhibit a CAGR of 5.4% over the forecast period 2024 to 2030.

Key Takeaways

Key players operating in the Industrial Automation and Control Systems are LG Chem, Hanmi Pharmaceutical Co., Ltd., Boryung Pharmaceutical Co., Ltd., Novartis AG, EirGenix, Inc., Biocon Limited, G.L. Pharma GmbH, Daewoong Pharmaceutical Co., Ltd., Sandoz International GmbH, Boryung Pharmaceutical Co., Ltd., VHB Life Sciences Limited, HanAll Biopharma, Taiba Healthcare, Huons Co., Ltd., Dong-A ST Co., Ltd. The major players are focusing on partnerships, new product launches and strategic collaborations to expand their market share.

The rising investments in factory automation by automotive and electronics manufacturers present significant growth opportunities. Furthermore, technological advancements in AI, machine learning, predictive maintenance and IoT are enabling the development of smarter and more efficient automation solutions.

The growing adoption of robots, autonomous vehicles, digital twin technology and AI-based process optimization tools are making industrial operations more advanced. Technologies like augmented reality, human-robot collaboration and cloud computing for remote asset performance monitoring are also gaining widespread acceptance.

Market Drivers

The key drivers contributing to the growth of Industrial Automation And Control Systems Market are growing emphasis on maximizing productivity, reduction in production costs and minimizing human errors. With technological evolution, automation is becoming more affordable and can help organizations significantly enhance their return on investment from automation projects. Furthermore, factors like increasing complexity in production processes coupled with urgent need to improve flexibility are propelling more manufacturers to automate their facilities using advanced control systems. This is expected to continue fueling the demand during the forecast period.

Current challenges in Industrial Automation and Control Systems Market

The industrial automation and control systems market is facing several challenges currently such as cyber security threats, lack of skilled workforce, high initial cost of implementing advanced automation systems and complex integration of automation solutions with existing process infrastructure. Cyber attacks on industrial control systems have increased in recent times affecting operations, security and safety of industrial facilities. Lack of skilled professionals who can handle advanced automation technologies is also a major concern for companies. High costs involved in procurement and implementation of latest automation solutions especially in small and medium enterprises also restrict wider adoption of these technologies. Integrating new control systems with legacy equipment in the plant also demands substantial engineering efforts and downtime.

SWOT Analysis

Strength: Industrial automation solutions help improve operational efficiency, minimize downtime and reduce human errors. Advanced technologies enable remote monitoring and management of distributed assets.

Weakness: High costs of advanced automation technologies restrict their adoption among small businesses. Lack of in-house expertise to handle complex automation projects.

Opportunity: Growing demand for industrial IoT platforms and use of AI/ML technologies in process control and predictive maintenance presents new business opportunities. Adoption of cloud computing in industrial automation can reduce infrastructure costs.

Threats: Vulnerability of industrial control systems to cyber attacks is a major security concern. Disruptive technologies from new market entrants may make existing automation solutions obsolete rapidly.

Geographical regions with high market concentration

North America currently dominates the global industrial automation and control systems market in terms of value, accounting for more than 30% revenue share. Significant presence of large industrial automation vendors and early adoption of latest automation technologies among process and discrete manufacturing facilities in U.S. and Canada drives the North America market. Asia Pacific region is also expected to offer high growth opportunities owing to rapid industrialization and factory automation initiatives by China, India, Japan and South Korea.

Fastest growing region

Asia Pacific region is poised to be the fastest growing regional market for industrial automation and control systems during the forecast period. China is leading industrial automation adoption in the region aided by government initiatives like ‘Made in China 2025’. Presence of emerging economies with growing manufacturing sector, increasing investments in infrastructure projects and focus on factory automation to enhance productivity will propel the APAC market for industrial automation systems. Countries like India, Indonesia, Malaysia, Thailand and Vietnam are anticipated to generate substantial demand.