Silicon is the second most abundant element in the Earth’s crust and comprises nearly a quarter of the Earth’s mass. One of its most common and useful forms is silica, otherwise known as silicon dioxide (SiO2). While silica is found throughout nature in many forms like sand, flint, and quartz, it requires specialized high temperature processing to be converted into its high purity form suitable for various industrial applications. In this article, we will explore the uses of high purity silica in modern technology and its importance.

What is High Purity Silica?

High purity silica refers to silica that has been processed to contain 99.99% or greater silicon dioxide with very low levels of impurities. Common impurities removed during processing include aluminum, iron, calcium, sodium, and potassium oxides. High purity silica is manufactured through processes like acid leaching, chemical purification, or plasma melting which allows impurities to be precisely controlled down to parts-per-billion. This level of purity is crucial for its usage in various applications that we will explore below.

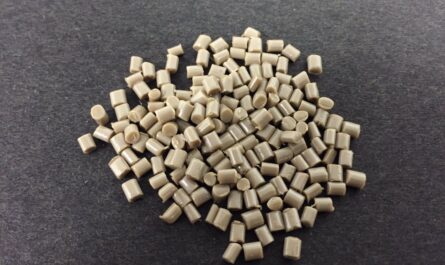

There are different types and forms of high purity silica available depending on the particular industrial needs:

– Fumed Silica: Produced through flame pyrolysis, it results in microscopic, amorphous spherical particles well suited for applications requiring large specific surface area. Common uses include reinforcing resins, printing inks, coatings, caulks and sealants.

– Precipitated Silica: Made through a wet chemical process, it has a more porous structure compared to fumed silica. Used in paints, rubber, plastics, animal feed, food, dental applications, etc.

– Silica Gel: A type of precipitated silica dried into a fine, hard solid that can readily absorb water molecules from the surrounding atmosphere via adsorption. Widely used as a desiccant in packaged foods and pharmaceuticals.

– Cristobalite and Tridymite: Naturally occurring high temperature crystalline forms of silica used where strength and thermal stability is required like in ceramics, glass, refractories, insulation fibers, etc.

Uses in Semiconductors and Electronics

One of the most important usages of high purity silica is in the semiconductor and electronics industries where it acts as a base material or processing aid. Some key uses include:

– Silicon Wafers: The purified foundation for all modern integrated circuits, memory chips, and microprocessors. High purity quartz crystals are melted and grown into ultrapure silicon ingots and sliced into wafers.

– CMP Slurries: Used to chemically mechanically polish silicon wafers during the fabrication of semiconductor devices. Fumed and precipitated silicas disperse abrasives while protecting features on the wafer surface from scratches.

– Insulation and Passivation Layers: Amorphous forms of silica serve as electrical insulators on electronics as well as protective passivation coatings on chips and circuitry to prevent corrosion.

– Fiber Optics: High Purity Silica fused silica glass fibers transmit data at the speed of light over vast distances. Their low attenuation and mechanical strength enable global telecommunications.

– LEDs and Photovoltaic Panels: Silica compounds make LED bulbs efficient by improving light extraction and heat dissipation. They form anti-reflective and encapsulation layers to boost solar cell performance.

Other Important Applications

Beyond electronics, high purity silica sees wide deployment in many other strategic industries:

– Tires: Silica-based reinforcing fillers dramatically improve tire performance in wet traction, braking, handling, and rolling resistance. Global demand is projected to grow.

– Detergents: Hardwater-tolerant builders and anti-caking agents based on precipitated silica aid washing and rinsing effectiveness in automatic dishwashing and laundry detergents.

– Agriculture: Feed-grade fumed silica enhances nutrient uptake and health of livestock. Silica gel maintains freshness of packaged foods.

– Personal Care: Thickeners and carriers in cosmetics, toothpastes, and skincare based on fumed and nano silicas. Their smooth textures are preferred by consumers.

– Gas Separations: Porous precipitated silica monoliths selectively filter gas mixtures through complex adsorption mechanisms for industrial and medical uses.

– Glass & Refractories: Dense forms like cristobalite withstand corrosion and impart strength at high kiln temperatures. Critical for container manufacturing.

– Water Filtration: Granular silica filters and membranes purify water by physically blocking particulates and pathogens. Silica sols coagulate contaminants for removal

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it