The cells of the geocells are usually rectangular, honeycombed or triangular in cross-section and are connected together to form a flexible mat or panel that can easily be laid down in place. Geocells have emerged as a revolutionary innovation in the construction industry that provides multiple benefits over traditional construction methods.

What are Geocells?

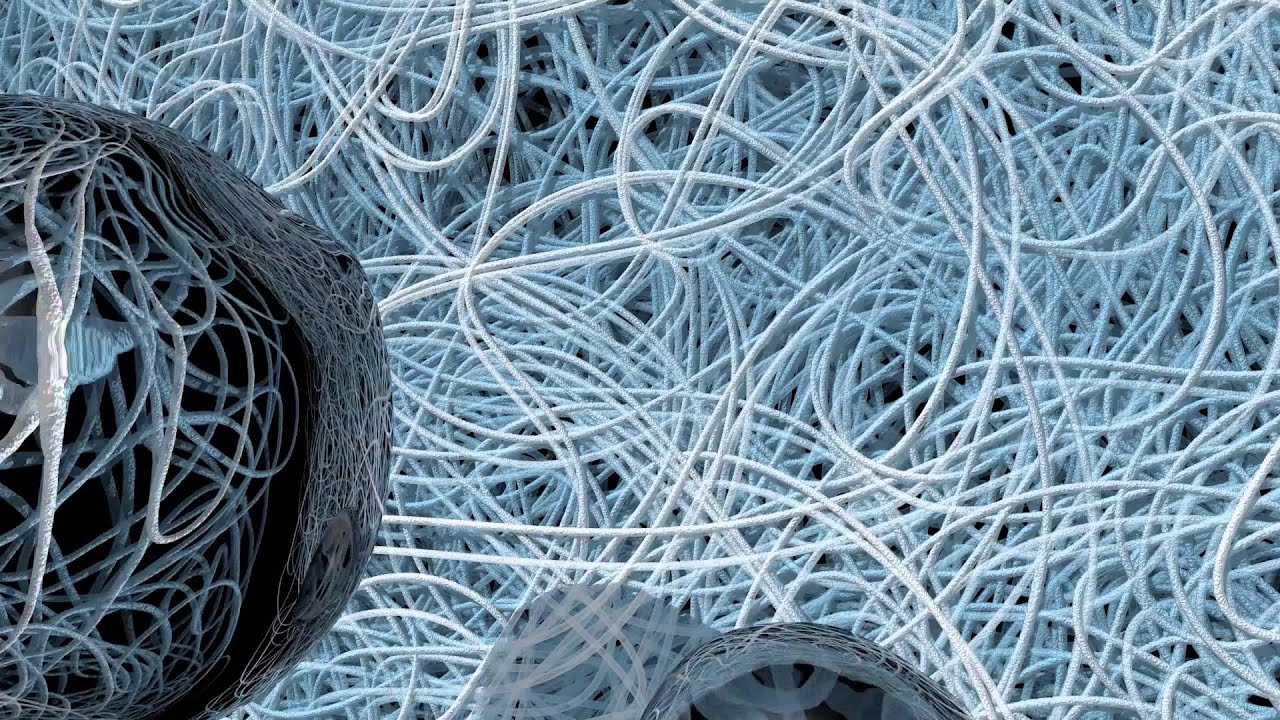

Geocells are three-dimensional mats consisting of interconnected wall elements that form individual cells. When filled with soil or aggregate materials, geocells create a reinforced layer or platform able to withstand tensile, compressive and shear stresses. The cells are typically rectangular, triangular or hexagonal in cross-section and can vary in height from a few centimeters up to several meters depending on the intended application and required load-bearing capacity. Geocells are made from UV-stabilized high-density polyethylene (HDPE) which makes them durable, lightweight and high strength.

Uses of Geocells

Geocells find a wide variety of uses in civil construction projects and infrastructure development due to their advantageous properties. Some major applications of geocells include-

Road Construction – Geocells are used for stabilizing shoulder slopes of roads, repairing shoulders and berms, and providing structural support to base courses under asphalt overlays. The geosynthetic cells reinforce the unpaved shoulders and prevent erosion.

Slope Protection – Geocells are employed for stabilization and revegetation of slopes prone to erosion, such as slopes near highways, waterways and steep terrain. The cellular structure confines infill soils and vegetation root masses to protect against sliding and slumping.

Retaining Walls – For building retaining walls Geocells are filled with compacted backfill to construct reinforced soil retaining structures. The cellular nets increase the tensile strength and load distribution capacity of these walls.

Channel Lining – In hydro-engineering projects involving lining of drainage ditches, chutes and spillways, geocells effectively armor the channels against frictional wear and hydraulic forces of flowing water.

Subgrade Stabilization – As a sub-base reinforcement material below roads, rail tracks or runways, geocells add structural integrity to the subgrade layer over weak or wet soils.

Benefits of Using Geocells

The engineered honeycomb cellular structure of geocells brings about numerous advantages for construction applications:

– Reinforcement – Cells interconnected in three dimensions form an infilled reinforced layer many times stronger than unreinforced fill. This reinforcement capability is utilized in construction of retaining walls, pavement subgrades etc.

– Confinement – Individual cells act as confinement cages pocketing and anchoring the infill soils or lightweight fill to increase shear resistance. This resists stresses from compaction, settlement and water erosion.

– Load Distribution – Trapezoidal/hexagonal cell shapes provide a grid framework distributing excessive loads from heavy vehicles or equipment across a broader reinforced surface area.

– Drainage – Geocell lateral walls allow for free drainage of water through the cells while retaining the infill. This prevents erosion and hydrological failures beneath construction.

– Vegetation Growth – Cells provide an ideal microclimate and anchorage for establishing vegetation on steep slopes or vegetation-lined channels. Roots can grow through the cells to stabilize slopes.

– Lightweight – Being made of HDPE plastic, geocells are highly portable and lightweight compared to conventional building materials like concrete or rocks used for similar applications.

– Cost Effective – Although initial costs may be higher than conventional methods, geocells provide significant lifecycle cost savings due to reduced long-term maintenance needs of reinforced soil structures.

Advancing Technology in Geocells

Continuous research and development is enhancing the capabilities of geocells. Some emerging trends include development of:

– Three-dimensional geocell mats incorporating vertical joints for out-of-plane stability in retaining wall backfills.

– Geocell strips and panels of diverse sizes suitable for micro-scale or large-scale infrastructure projects.

-Vegetated geocell systems integrating live stakes and seeds/cuttings within the cells to hasten vegetation establishment on construction sites.

-Biodegradable geocells made from natural fibers like coir, jute or paper pulp offering sustainability advantages.

-Infill geocell products pre-filled with proprietary lightweight grow-mix or aggregate-rich materials for one-time installation at sites.

-Reinforcement geotextiles laminated internally or externally on geocells to add interfacial shear strength at cell boundaries.

With their structural effectiveness and versatility proven worldwide over decades, geocells have become an essential weapon in the toolbox of civil engineers. Today geocells are revolutionizing construction approaches and Green techniques across industries from transportation, infrastructure development, mining and agriculture. As manufacturing technologies continue optimizing geocell product design, more innovative applications are certain to emerge, cementing geocells as a dominant geo-material of the future.

Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it