Ferro manganese is a brittle, silvery-grey hard metal that is primarily used as a nodularizing and alloying additive in steel production. It consists of manganese content ranging between 65-80% along with other ingredients like iron, carbon and silicon. Being a ferroalloy, it enhances various properties of steel like strength, toughness, corrosion resistance and machinability. In this article, we will discuss in detail about ferro manganese, its manufacturing process, uses,size and outlook.

What is Ferro Manganese?

It is usually available in the form of spherical or irregular lumps. Based on the manganese content, ferro manganese is classified into different grades like low carbon ferro manganese (65-79% Mn), medium carbon ferro manganese (80-85% Mn) and high carbon ferro manganese (over 85% Mn). The production of ferro manganese involves reducing manganese oxide ore in a blast furnace using metallic iron and carbon as the reducing agent.

Ferro Manganese Manufacturing Process

The key stages involved in ferro manganese manufacturing are:

– Ore Preparation: Raw manganese ore is crushed and screened toliberate manganese minerals from gangue materials.

– Sintering: The crushed ore is mixed with coke/coal and sintered to agglomerate fine particles prior to reduction.

– Reduction: Sintered ore, carbon source and flux is charged in a blast furnace where manganese oxide reacts with carbon at high temperature (around 1100°C – 1300°C) to produce ferro manganese. Iron acts as the collector metal.

– Furnace Operations: In the blast furnace, maintaining ideal furnace temperature, perfect blend of raw materials and control over air flow is critical for consistent production.

– Post Processing: Molten Ferro Manganese from the furnace bottom is either cast directly into moulds to form ingots or solidified in ladles to shape convenient sizes for transportation.

Major global producers of ferro manganese include South Africa, Ukraine, India, Iran and Gabon where availability of manganese ore and availability of coal as reducing agent are favorable.

Uses of Ferro Manganese

The primary use of ferro manganese is in steel production where it is used as a key alloying and nodulizing agent. Some of the major uses are:

– Steel Production: Ferro manganese is an essential input in steelmaking where manganese enhances properties like strength, toughness, wear resistance and machinability of steel.

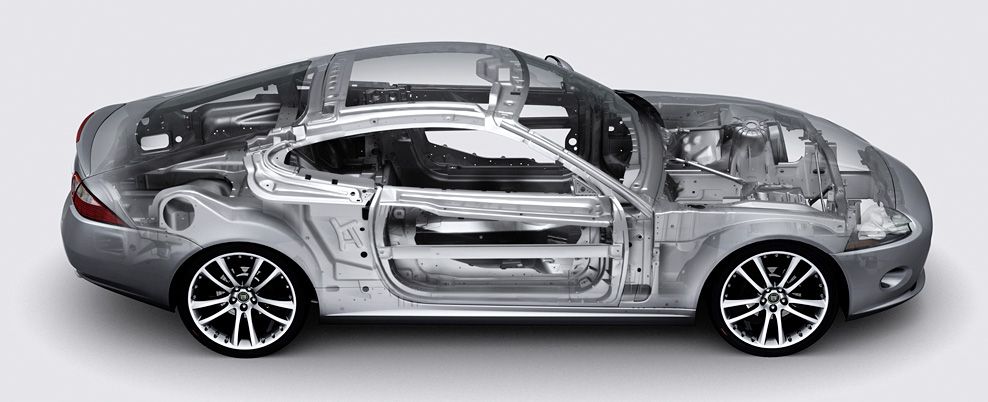

– Cast Iron Production: Adding small amount of ferro manganese improves mechanical properties and castability of cast iron which is used to make machinery parts.

– Desulfurization: Manganese has strong affinity for sulfur and gets sulfur out of molten iron which would otherwise make the steel brittle.

– Nodulization: Ferro manganese promotes formation of spherical graphite nodules in ductile iron giving it greater flexibility and tensile strength.

– Alloy Steel: Stainless steel and other alloy steels like Hadfield manganese steel uses ferro manganese as the chief alloying element.

Besides steel industry, ferro manganese also finds applications in production of batteries, ceramics, fireworks and matches where its oxidation properties are utilized.

Ferro Manganese and Outlook

The global ferro manganese size was estimated at over USD 9 billion in 2019 and is projected to grow steadily at around 3-4% annually driven by rising steel demand worldwide. Asia Pacific currently dominates the led by China, Japan and India while major import s re in Europe and North America. Over the years, production capacities are rising in developing Asian and African countries with availability of manganese resources. However, volatility in manganese ore prices presents major challenge. With growing Infrastructure development and auto sector expansion, the overall outlook for ferro manganese remains positive over medium term.

To summarize, ferro manganese is a critical raw material input for steel sector owing to its unique alloying properties. The manufacturing, applications, global production landscape and

outlook indicate growing relevance of this ferrous alloy in diverse industries. Sustainable availability along with efficient utilization holds key in fulfilling the rising steel demand while balancing cost competitiveness.

Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it