With Distributed Acoustic Sensing (DAS) emerging as a game-changing technology for pipeline monitoring, oil and gas companies are increasingly adopting this innovative solution to gain enhanced situational awareness of their critical infrastructure and operations. DAS offers comprehensive and continuous monitoring of vast pipeline networks using the fiber optic cables already deployed for telecommunications. Let us take a detailed look at this revolutionary acoustic monitoring technique and how it is transforming pipeline safety and security.

What is Distributed Acoustic Sensing (DAS)?

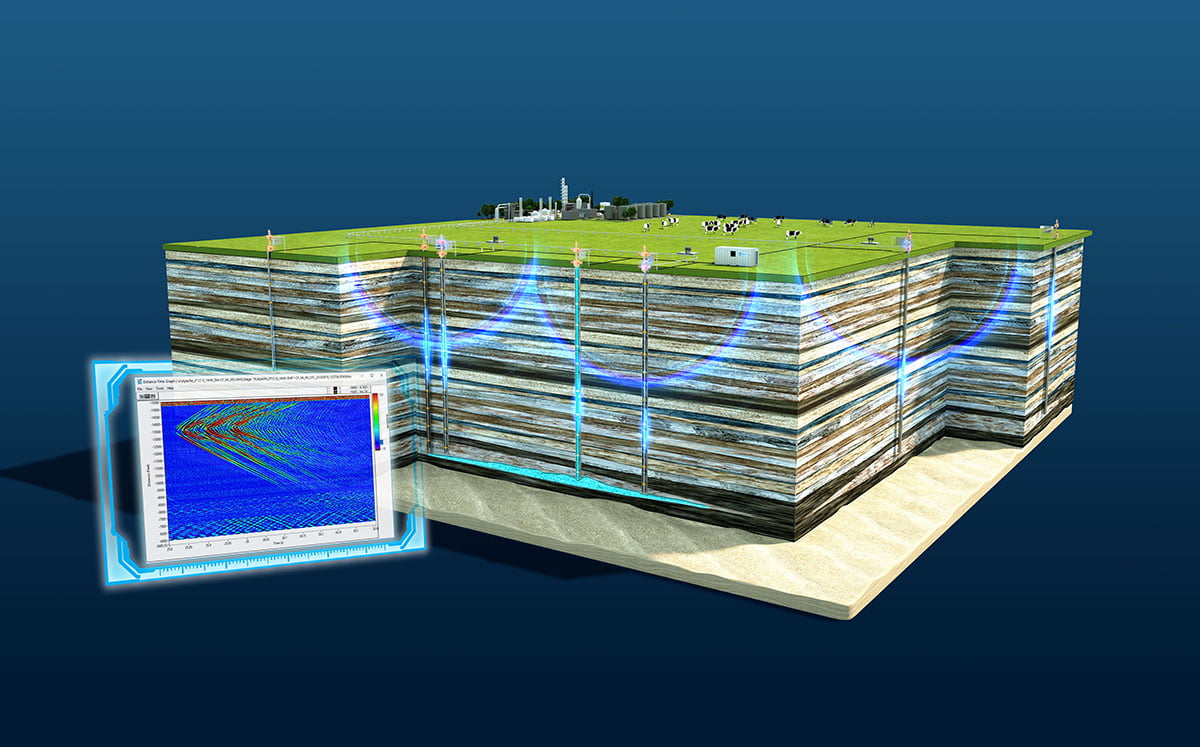

Distributed Acoustic Sensing (DAS) or DAS is an optical fiber-based sensing technique that enables the detection and localization of acoustic signals along the entire length of a fiber cable. In a typical DAS setup, laser pulses are sent down the fiber and any vibrations present along the cable cause Rayleigh backscatter in the light. Sophisticated sensing instruments can analyze this backscattered light and detect the location and nature of acoustic events happening near the fiber.

Unlike traditional point sensors, DAS utilizes the entire fiber as a distributed sensor, giving it the unique ability to monitor multiple pipeline points simultaneously over extended distances ranging from tens of kilometers to hundreds of kilometers. This distributed sensing capability allows DAS systems to offer continuous acoustic surveillance of pipelines with high spatial resolution, detection sensitivity and threat localization accuracy.

Applications of DAS in Pipeline Monitoring

Some of the key applications of DAS technology for pipeline monitoring include:

– Third party interference detection: DAS can detect unauthorized excavation or contact with the pipeline like digging, drilling or construction activity in the vicinity. This helps operators identify and address risks from third party damage early on.

– Leak detection: Even small leaks emit acoustic signatures that DAS sensors can pick up. Continuous monitoring allows leaks to be pinpointed promptly before they escalate into environmental or safety hazards.

– Hydraulic fracturing monitoring: DAS provides a means to continuously monitor high-pressure hydraulic fracturing operations and quickly identify any problems at different fracturing stages and wellheads.

– Pig tracking: The movement of pipeline inspection gauges or “pigs” can be tracked in real-time using DAS for integrity assessment and to locate blockages.

– Material theft alert: Unauthorized taps into gas or product lines result in conspicuous acoustic events and DAS helps detect such theft early.

– Surveillance against criminal intrusions: DAS acts as a force multiplier for security teams by remotely monitoring pipeline routes against threats like vandalism or sabotage.

Advantages of Distributed Acoustic Sensing (DAS) over Traditional Technologies

Compared to alternative monitoring solutions, DAS offers several distinctive advantages:

– Continuous coverage: Unlike point sensors, a single DAS sensor can continuously monitor hundreds of kilometers of distributed pipeline infrastructure.

– High sensitivity: DAS can detect very faint vibrations that traditional microphones may miss, even pinpointing the location of small leaks.

– Future-proofing: DAS leverages existing fiber networks so no additional infrastructure investment is needed for monitoring. Fiber doesn’t degrade over time either.

– Cost-effectiveness: With no need for electrical power or communication lines at sensor points, DAS results in lower upfront costs and operating expenses than alternatives.

– Tamper-proof: Since the sensing is non-electronic and performed remotely, there is no risk of DAS equipment being damaged, moved or hacked locally.

– Synergy with SCADA: DAS data streams can be integrated with existing pipeline SCADA and control systems for centralized monitoring and automated alarmed responses.

Widespread Adoption of DAS

Given the myriad advantages, leading energy companies across the world have started deploying DAS at an expanding scale to monitor critical midstream oil and gas assets as the primary monitoring solution or to augment traditional systems. Pipeline operators value DAS for achieving continuous visibility, improving response times, enhancing regulatory compliance and demonstrating diligence in leak detection to stakeholders. Both new-build and retrofit installations are rising sharply as DAS gains a strong foothold as the technology of choice for next-generation pipeline protection globally.

Going forward, we can expect further technological developments that boost the performance and commercial viability of DAS. The increasing digitization of pipeline infrastructure also provides new opportunities to optimize DAS deployments through analytics and automation. As safety, reliability and sustainability become priorities across the energy industry, Distributed Acoustic Sensing (DAS) will undoubtedly play a pivotal role in shaping the future of pipeline monitoring worldwide.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it