The Cyanate Ester Resins market is estimated to be valued at US$ 211.8 million in 2023 and is expected to exhibit a CAGR of 8.6% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

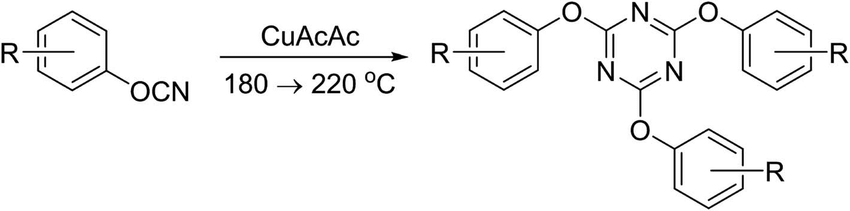

Cyanate ester resins are thermosetting resins characterized by high glass transition temperature, low moisture absorption, and exceptional temperature resistance. They are derived from bisphenol-based monomers that react with cyanate ester groups to form molecular rigid structures. Cyanate ester resins find application in variety of end-use industries such as aerospace & defense, electrical & electronics, and others owing to their superior properties.

Market Dynamics:

The market is primarily driven by growing demand for cyanate ester resins from aerospace & defense industry. Cyanate ester resins are highly preferred in aircraft structures and components due to their high strength, durability, and heat resistance even at elevated temperatures. Additionally, increasing usage of cyanate ester resins in printed circuit boards (PCBs) and electrical insulation is also fueling market growth. Cyanate esters possess very low coefficient of thermal expansion, high electrical resistivity, and excellent moisture & chemical resistance. These properties makes them suitable for applications where high reliability and continuous operation over wide temperature ranges is required.

SWOT Analysis

Strength:

– Cyanate ester resins have high heat resistance and excellent dielectric properties, making them suitable for high temperature applications. They offer strength and stiffness even at elevated temperatures.

– These resins provide good resistance against hydrolysis and moisture absorption. They retain their dimensional stability and mechanical properties when exposed to humidity.

– Cyanate ester resins bond well to metals like copper and produce strong adhesive bonds with low void content.

Weakness:

– The processing and curing of cyanate ester resins involve high temperatures of around 180°C which increases production costs.

– They have a higher viscosity and require specialized manufacturing processes compared to epoxy resins. This increases costs and complexity.

Opportunity:

– Growth of end-use industries like aerospace, electronics and defense is driving demand for high performance resins suitable for applications in extreme operating conditions. This provides opportunities for cyanate ester resins.

– Increasing R&D on development of newer cyanate ester resin formulations with improved processability, toughness and environmental sustainability.

Threats:

– Availability of alternative high performance thermoset resinslike polyimides and benzoxazines pose competition.

– Fluctuations in prices of raw materials used in cyanate ester resin manufacturing.

Key Takeaways

The Global Cyanate Ester Resins Market Size is expected to witness high growth, exhibiting CAGR of 8.6% over the forecast period, due to increasing demand from aerospace industry. The aerospace industry requires materials that can withstand high temperatures without degradation. Cyanate ester resins meet this demanding performance requirement making them widely used in the aerospace industry.

Regional analysis

North America is expected to dominate the global cyanate ester resins market during the forecast period. Abundant availability of raw materials and presence of major players in the region is driving the market. The Asia Pacific region is expected to be the fastest growing market for cyanate ester resins owing to rapid growth of end-use industries such as aerospace and electronics in countries like China and India.

Key players

Key players operating in the cyanate ester resins market are Huntsman, Lonza, Techia Corporation, TenCate, Cytec, Hexcel, Jiangdu Maida Group, Carbon Fibre Technology, Isola Group, Adeka, SGL Carbon, Gurit, Chongqing Guijie Technology, Shanghai Hunsman Material, Taixing Suning Chemical, Hengyu New Material, Natong Chemical, Kangda New Materials, Jiafu Technologh, Tianma Group. The players are focusing on new product launches and expansion strategies to gain higher market share.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it