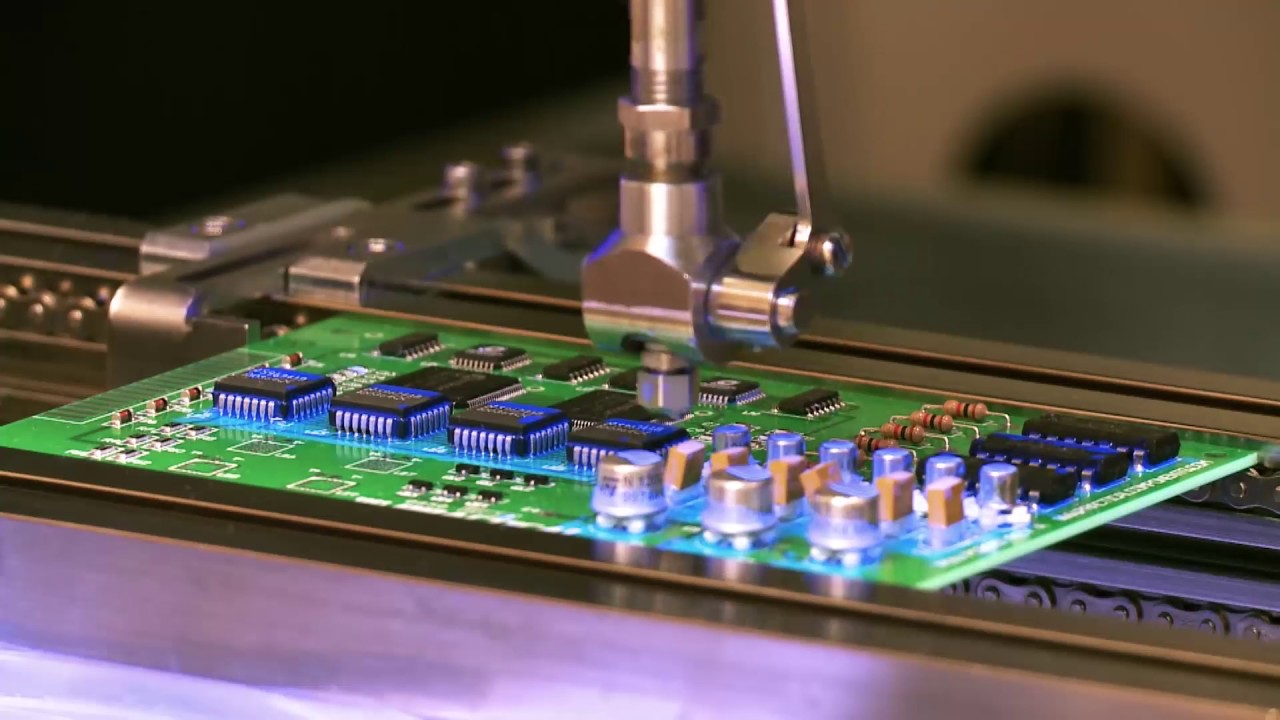

Conformal coating is an essential process in printed circuit board (PCB) manufacturing and repair. It provides protection to the PCB from various environmental factors. However, there are times when the coating needs to be removed, for example during rework or repair. This is where conformal coating strippers play a vital role. In this article, we will discuss what conformal coating strippers are, their different types and how they work.

What is a Conformal Coating Stripper?

A conformal coating stripper is a chemical solution used to safely remove protective conformal coatings from printed circuit boards and electronic assemblies. Conformal coatings like acrylic, silicone, polyurethane, etc. are applied post-soldering on PCBs to shield the circuitry from moisture, chemicals, dust and other environmental hazards. However, there may be instances where the coating needs removal during rework, repair or modification. That’s where conformal coating strippers come in handy to dissolve and lift off the conformal coat without causing any damage to the PCB.

Types of Conformal Coating Strippers

There are different types of Conformal Coating Stripper available based on the type of coating they can remove:

– Acrylic Coating Stripper: Used for removing flexible coating and water-based acrylic coatings. Solvents in such strippers soften the acrylic allowing it to peel off easily.

– Polyurethane Coating Stripper: Effective in dissolving polyurethane, urethane and similar coatings. The strippers typically contain methylene chloride or other halogenated solvents.

– Silicone Coating Stripper: Formulated to remove silicone conformal coatings which are tougher than acrylic or polyurethane. Silicone strippers contain solvents like trichloroethylene or dimethyl sulfoxide (DMSO).

– Universal Coating Stripper: As the name suggests, universal strippers can remove a wide range of conformal coatings like acrylic, silicone, polyurethane, etc. They usually have a blend of solvents that act on different coating types.

How do Conformal Coating Strippers Work?

The basic principle behind all conformal coating strippers is that they contain solvents which dissolve and soften the protective coating when applied on the PCB. Here are the typical steps involved in using a coating stripper:

– Apply the stripper using a brush, spray bottle, etc. on the area where coating needs to be removed.

– Allow some time (2-10 minutes depending on type of coating and stripper used) for the chemicals to interact and dissolve the coating.

– Scrape or wipe off the softened coating using a spatula, paper towels, etc. This lifts off the coating from the PCB surface.

– Repeat the application and removal process if some coating still remains.

– Once all coating is removed, clean the PCB thoroughly with solvent to remove any stripper residue.

This solvent-based process is safer than mechanical scraping which can potentially damage components. The stripped PCB can then be reworked or repaired.

Safety Precautions for Using Conformal Coating Strippers

While conformal coating strippers effectively remove protective coatings, certain safety measures need to be followed as most contain hazardous chemicals:

– Use strippers only in well-ventilated areas or with fume extraction as they release volatile organic compounds (VOC).

– Wear protective equipment like gloves, goggles during handling and application to prevent skin and eye contact.

– Avoid contact of strippers withAny moisture, sparks or open flames as many are flammable.

– Refer product SDS and follow manufacturer guidelines for storage, disposal and first aid in case of accidental exposure.

– Monitor stripped boards for complete removal of any residues before re-assembly to prevent damage.

conformal coating strippers are indispensable tools for PCB rework and repair technicians. They efficiently dissolve various types of conformal coatings applied on circuit boards without causing damage. Choosing the right stripper based on the coating material and following safety practices ensures a smooth and safe coating removal process. This helps retrieve boards for necessary modifications in a cost-effective way.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it