Adhesive tapes, also known as pressure-sensitive tapes, are one of the most commonly used items in our daily lives. From sealing packages to holding up posters to mending small cuts and wounds, adhesive tapes have applications across various industries and households. In this article, we will discuss the history of adhesive tapes, different types of adhesive tapes available in the market, their uses, manufacturing process and latest developments in adhesive tape technology.

History of Adhesive Tapes

The origins of adhesive tapes can be traced back to late 19th century when the medical adhesive strips were developed for wound dressing. The modern adhesive tapes were invented in the 1920s when Richard Drew, working for 3M company developed the first masking tape by adding an adhesive coating to a backing material. This breakthrough invention led to development of multiple commercial products using pressure-sensitive adhesives. Some key developments in adhesive tape history include cellophane tapes introduced in 1930s, medical adhesive bandages in 1940s and scotch tapes in 1950s which became a household name.

Types of Adhesive Tapes

There are various types of adhesive tapes available today based on their composition, adhesive properties and intended uses. Some of the commonly used adhesive tape types are:

Masking Tapes: Made from crepe paper or plastic film backing with low adhesion properties, masking tapes are used to protect surfaces temporarily during painting, construction etc.

Packaging Tapes: These durable tapes made from polypropylene or polyethylene backings with high adhesion are used for sealing boxes and packaging items. Scotch tape andpacking tapes fall under this category.

Duct Tapes: Featuring a sturdy cloth or plastic backing coated with rubber-based adhesive, duct tapes are known for their strong bonding and versatility in household repairs.

Medical Tapes: Made with materials approved for skin contact like non-woven fabric or paper backings coated with acrylic adhesives, medical tapes are used for wound dressing, bandages etc. Some examples include surgical tapes and medical adhesive bandages.

Electrical Tapes: Developed specifically for insulation and bundling applications in electric wiring, these tapes have plasticized vinyl chloride backings resistant to heat, moisture and abrasion.

Uses of Different Adhesive Tapes

Adhesive tapes have diverse applications across industries due to their easy adhesion and removal properties. Some key uses of different types of tapes are:

– Masking tapes are used for painting, decorating, construction projects to section off areas. They protect surfaces while work is in progress.

– Packaging tapes are the primary choice for shipping, closing boxes and bundling items. They provide sturdy seals for logistics and storage.

– Duct tapes are a universal household problem solving tape due to their toughness and adhesion. Uses include repairs, holds, connectors for various projects.

– Medical adhesive tapes are essential wound and bandage tapes used across hospitals and first aid kits for cuts, bandages etc.

– Electrical tapes are used extensively in electrical installations and repairs for insulation, bundling wires and providing protective layers.

Manufacturing Process

The basic manufacturing process of most adhesive tapes involves:

– Production of backing material like paper, film, cloth using processes like paper making, film extrusion etc.

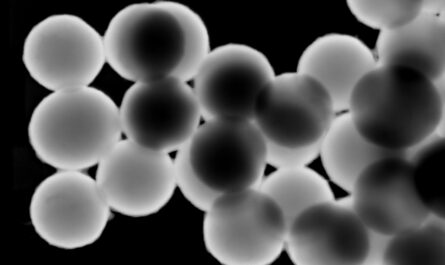

– Coating of adhesive compound which is a blend of polymers, resins and additives onto the backing material using machines like roller coaters.

– Drying and curing of adhesive under controlled temperature.

– Slitting or cutting into desired widths and packaging into rolls.

– Additional processes may include printing, laminations depending on end product.

Quality is ensured through stringent testing at various stages to check properties like adhesion, strength, temperature and chemical resistance. Automated high speed lines are common for mass production.

Latest Advancements

Research and innovation is ongoing to develop advanced adhesive tapes with improved features. Some latest trends seen are:

– Healthcare and medical grade tapes are being made with nanofibers, hydrogels to conform better to skin and provide occlusion without pain on removal.

– Double sided tapes and mounting tapes are gaining popularity for applications like mounting displays, stickers due to their high bond strength.

– Specialty tapes with advanced adhesives are available for applications in aggressive environmental conditions like oil & gas industry.

– Bio-based adhesive tapes are being explored as sustainable alternatives made from plant derived materials.

– 3D and stretchable printed circuit boards are enabled using elastic and stretchable conductive adhesive tapes.

Adhesive tapes have revolutionized both industries and daily lives with their versatile applications. Constant innovation is expanding uses of tapes into new areas. As new technologies emerge, adhesive tapes will continue playing an important role through new product developments addressing diverse application needs.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it