Bioethanol: A Greener Fuel Source for the Future

Introduction

With growing concerns around climate change and dependence on fossil fuels, bioethanol has emerged as a promising renewable alternative fuel. Made from various plant biomass sources through fermentation and other processes, bioethanol serves as a cleaner burning fuel that can help reduce emissions. In this article, we explore what bioethanol is, how it is made, current production and usage, as well as the opportunities and challenges of this greener fuel source.

What is Bioethanol?

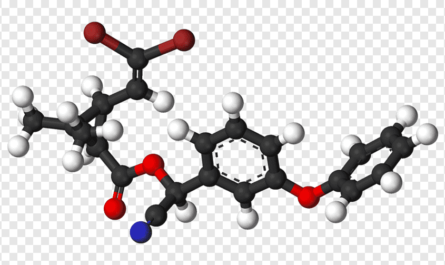

Bioethanol, also known as ethanol fuel or simply ethanol, is a type of alcohol made through the fermentation of sugars found in various plant materials such as corn, sugarcane, or cellulosic biomass. Specifically, bioethanol is ethyl alcohol (C2H5OH) which is produced either through sugar fermentation or starch hydrolysis followed by fermentation. Unlike ethanol for medical or industrial use, bioethanol is meant to be used as a fuel, mainly as a gasoline additive or extender to increase octane and improve vehicle emissions. As a renewable biofuel, it provides an alternative to gasoline with reduced greenhouse gas emissions over its lifecycle.

Production of Bioethanol

The production of bioethanol generally involves several steps. First, the plant biomass source like corn or sugarcane is cultivated and harvested. Then, the starch or sugars in the raw material are extracted through various processes. For starch-based feedstocks like corn, the starch needs to be broken down into fermentable sugars through a process called saccharification. For sugar-based feedstocks like sugarcane, the pre-existing sugars simply need to be extracted. Following this, yeast is added to the mashed or extracted liquid to start fermentation. As the yeast consumes the sugars, it produces ethanol and carbon dioxide. After fermentation, the ethanol is separated through distillation. The leftover solids can be used as animal feed. The purified ethanol is then ready to be blended with gasoline for transportation fuel use.

Current Production and Usage

Currently, the United States and Brazil are the two leading producers of bioethanol globally. In the US, over 90% of bioethanol production comes from corn starch. Over 15 billion gallons of corn ethanol were produced in 2019 to meet the Renewable Fuel Standard. Brazil on the other hand mostly uses sugarcane as the raw material, producing over 25 billion liters annually, allowing flex-fuel vehicles that can run on any ethanol-gasoline blend. Other countries like China and India have also started large-scale production from materials like cassava, sorghum or molasses. Overall, bioethanol accounted for about 5% of global road transport fuel in 2020. It is mainly used in vehicle fuel typically in blends up to 85% (E85) with gasoline. Total displacement of petroleum-derived fuels remains limited by infrastructure and technology challenges.

Opportunities in Cellulosic Ethanol

While first generation bioethanol production from corn and sugarcane has helped displace some fossil fuels, cellulosic ethanol presents opportunities for higher yields and more sustainable feedstocks. Cellulosic biomass including crop residues, forestry waste and purpose-grown grasses can be hydrolyzed into fermentable sugars instead of using edible starches and sugars. Abundant lignocellulosic materials like corn stover and wood waste accumulate annually, providing a large renewable resource. With advances in pretreatment and enzymatic hydrolysis methods, cellulosic ethanol could potentially unlock a cost-competitiveAdvanced Biofuel. While commercial production has faced challenges, countries like USÂ are ramping up demonstration plants with targets of 16 billion gallons from cellulosic sources by 2022. This next-generation biofuel offers 60-100% lower carbon emissions and does not compete with food on fertile agricultural land.

Challenges and the Road Ahead

Despite the progress, some challenges remain for widespread adoption of bioethanol. Limited arable land, water resources and crop yields means food versus fuel debates around first generation feedstocks. Infrastructure for higher ethanol blends requires investment beyond the E10 level. Public acceptance also influences policy targets. Cellulosic technologies are yet to achieve economies of scale and compete commercially without subsidies. Sustainability certification is important to ensure overall greenhouse gas savings over the fuel lifecycle. Overall, bioethanol certainly has potential as a transition fuel during electrification of transport. But maximizing its environmental and economic gains requires overcoming hurdles through collaborative efforts between researchers, industry and policymakers. With the right policy push and technological breakthroughs, bioethanol could play a meaningful role in the global transition to renewable fuels.

Conclusion

To summarize, bioethanol produced from various plant biomass provides a promising renewable alternative to gasoline that can reduce emissions. Current large-scale production relies mainly on corn and sugarcane, but cellulosic technologies offer higher yields without competing with food crops. Achieving sustainable commercial production at scale remains a work in progress due to technical and infrastructure barriers. However, with dedicated efforts, this greener fuel holds opportunities to supplement transportation needs during climate change mitigation. Continuous research coupled with supportive policies will be crucial to realize bioethanol’s potential as a bridge to low-carbon mobility.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it