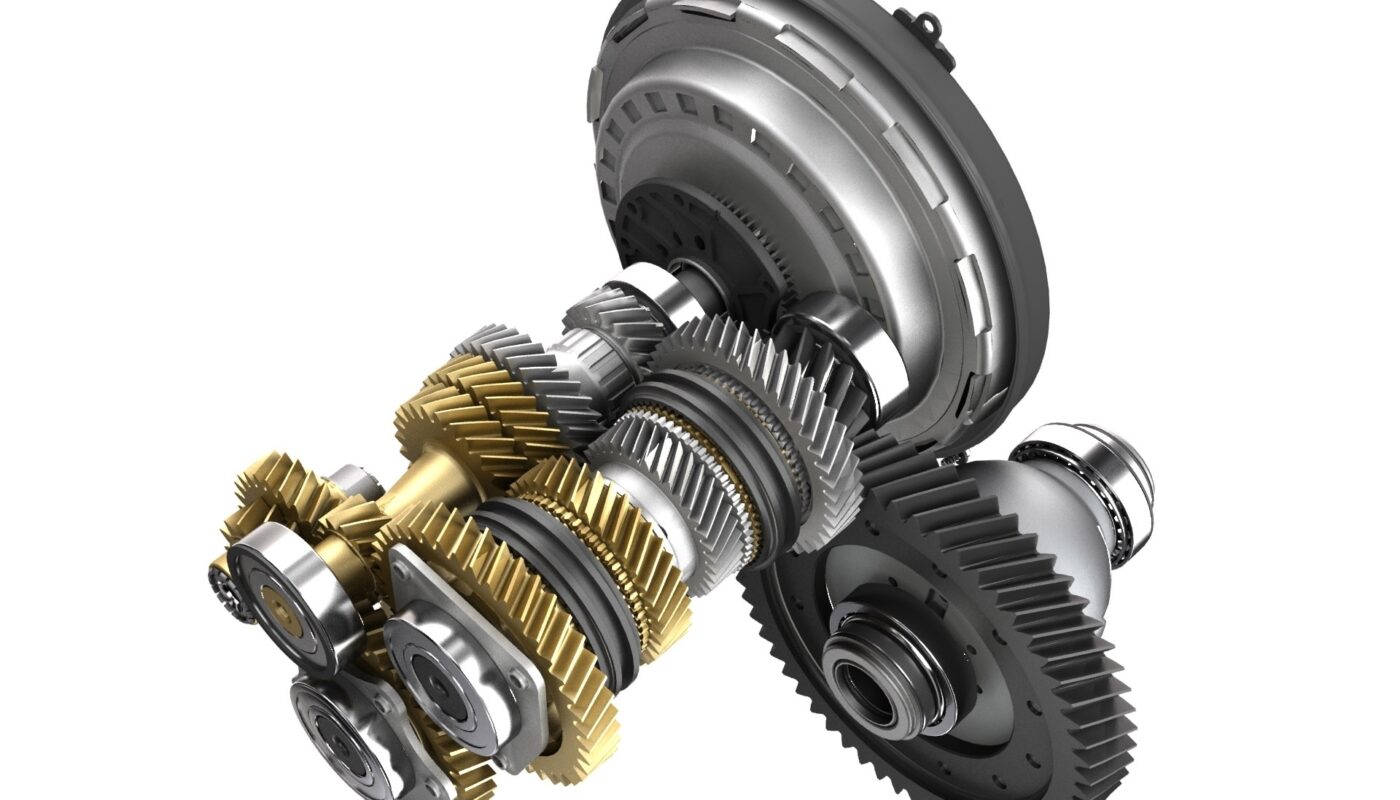

Automobiles wouldn’t function nearly as efficiently without precise and durable transmission gears working behind the scenes. While most drivers don’t give much thought to their vehicle’s transmission on a daily basis, this complex system of gears is essential for transferring power from the engine to the wheels in a smooth and controlled manner. Let’s take a deeper look at automotive transmission gears and appreciate their crucial role.

Types of Automotive Transmission Gears

There are two main types of transmission systems used in modern vehicles – manual and automatic. Both utilize gears, but they differ in how gears are selected and changed.

Manual Transmission Gears: As the name implies, manual transmissions require the driver to manually select gears using a clutch pedal and gear shift lever. Gears within the transmission are permanently meshed and a single gear engages at a time based on the driver’s input. Synchronizer rings allow for smooth gear changes.

Automatic Transmission Gears: Automotive Transmission Gears feature multiple planetary gearsets that allow seamless shifts between gears without driver involvement via a torque converter and fluid coupling. A computerized control module monitors factors like vehicle speed and engine RPM to select the optimal gear. Some modern automatics also offer manual shift modes.

Regardless of transmission type, the gearing within determines critical aspects of a vehicle’s driveability and performance like acceleration, top speed, fuel efficiency, and more. Gears come in a variety of designs, materials, and tooth counts to suit different applications.

Common Gear Designs and Materials

Spiral bevel gears: Often used in final drive applications, spiral bevel gears mesh at an angle to transfer torque between non-parallel shafts. Their beveled design helps minimize noise.

Helical gears: A helical cut provides each tooth with both axial and radial components, making these the quietest running gears. They are well-suited for transmission applications.

Straight-cut gears: Having a simple straight tooth profile, straight-cut gears are louder but less expensive to produce than other designs. They mainly see use in heavy-duty environments.

Hypoid gears: Used in rear axles, hypoid gears mesh at both an axial and helical angle for a compact design. However, their geometry produces more noise.

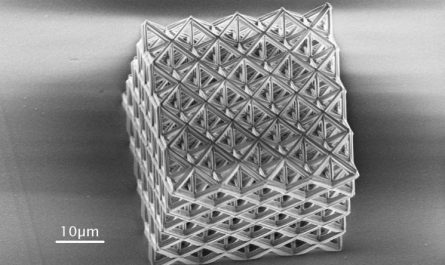

Most automotive gears are made of hardened steel alloys for their strength and wear resistance. Some performance and heavy-duty components employ stronger alloys like carbon steel. Lighter aluminum and composite plastic materials avoid extra weight in non-critical applications. Grease or oil lubrication keeps gears running cool and smooth.

The Role of Gear Ratios

A transmission’s gear ratios determine the relationship between the engine’s RPM and the vehicle’s road speed. By varying these ratios, drivers can keep the engine in its optimum power band for any given speed. Lower gears provide more torque (pulling power) for acceleration and hill climbing, while higher gears allow efficient high-speed cruising.

Automatic transmissions provide seamless shifts between 4-10 forward gears nowadays. Manuals commonly offer 5 or 6 gears for better control. Performance vehicles may have up to 8 forward ratios for precise tuning across a wide RPM range. The exact gearing is selected based on parameters like engine output, target performance specs, and fuel efficiency goals.

Quality is Key for Long Transmission Life

While transmission components undergo extensive testing and quality control from manufacturers, their long-term endurance depends much on proper maintenance. Routine fluid and filter changes expel contaminants that accelerate wear. Checking gear oil level and condition regularly catches small issues before they worsen. Having transmission fluids and filters serviced per manufacturer schedules optimizes smooth shifting and gear protection.

Drivers can also extend transmission life by avoiding frequent lugging in too high a gear, which overworks components. Going easy on aggressive launches and not exceeding the rated towing capacity prevents overload stresses. With care and high-quality parts, a transmission system should provide decades of reliable service.

Whether you drive a performance vehicle craving quick shifts or a basic economy car, transmission gears are empowering smooth mobility behind any drive. Though unseen, their complex synchronized meshing and carefully calibrated ratios optimize everything from acceleration feel to long-distance cruising. The next time you change gears seamlessly on the road, appreciate the unsung engineering brilliance that is your automotive transmission

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it