Automated storage and retrieval systems (AS/RS) have become an integral part of modern warehouses and distribution centers. An AS/RS uses automation to efficiently store, retrieve, and manage inventory using minimal human intervention. This article explores the benefits of AS/RS and how they have transformed warehouse operations.

What is an AS/RS?:

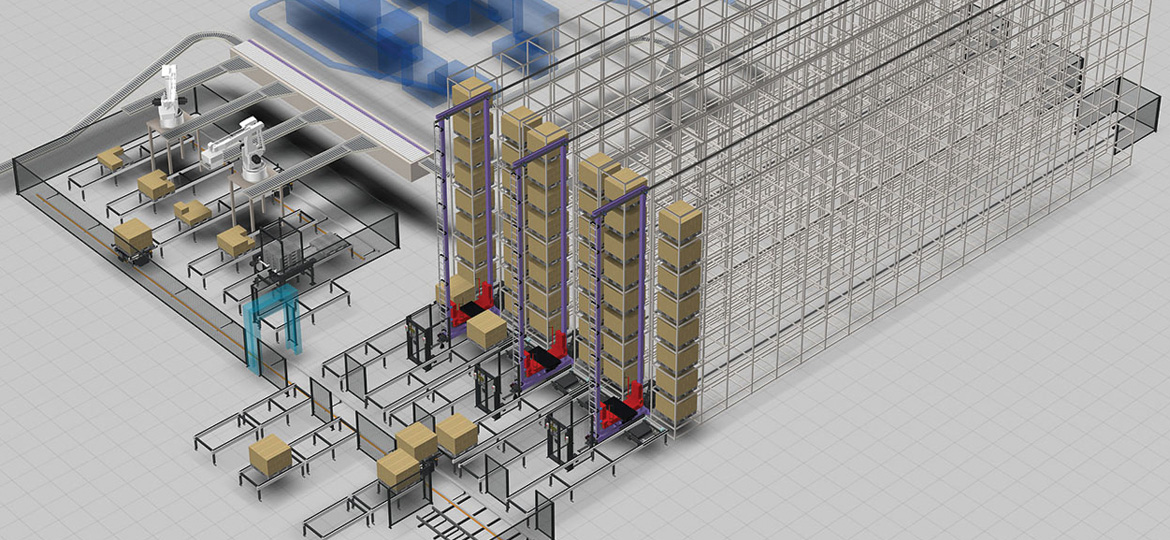

An automated storage and retrieval system (AS/RS) consists of computer-controlled storage and retrieval machines located within an automated warehouse. Pallets or cases of goods are placed onto storage and retrieval machines using lifts which then store or retrieve the loads from defined storage locations. The AS/RS machine uses robotic arms and grippers to pick up loads and shuttle them to or from storage racks or locations. Sensors and software determine the optimal storage locations and guide machines for efficient operations.

Advantages of AS/RS:

– Increased storage density: Automated Storage and Retrieval System allows warehouses to maximize available floor space with very narrow aisles. This results in up to 80% higher storage density compared to traditional racking systems.

– Improved inventory accuracy: AS/RS tracks inventory locations in real-time to ensure accurate bin-to-slot assignments. This reduces errors related to misplaced items.

– Higher productivity: Retrieval machines in AS/RS can process over 300 transactions per hour with sub-minute retrieval times. This is 3-4 times faster than standard manual operations.

– Lower labor costs: AS/RS requires fewer employees as storage and retrieval is largely automated. Labor needs are reduced by 30-50% compared to non-mechanized warehouses.

– Minimal inventory damage: Robotic arms and grips gently handle loads with No chances of accidental damage during puts and picks unlike manual operations.

– Real-time visibility: Business intelligence and asset tracking capabilities provide full visibility into inventory levels and locations in real-time.

– Flexibility: AS/RS systems can easily scale storage space up or down as inventory needs change. New racks or levels can be added as businesses expand.

Types of AS/RS:

There are mainly three types of AS/RS based on handling technologies used:

Rack Systems: Racks stacked horizontally or vertically hold storage bins or pallets. Cranes attached to horizontal rails pick loads from designated rack locations using forks or grippers. Shuttle rack systems use autonomous shuttles instead of cranes.

Carousels: Material handling system consisting of continuously moving racks arranged in a circular pattern. Storage locations rotate past a loading/unloading station where loads are deposited or retrieved by robots.

Vertical Lift Modules (VLM): Consist of multiple storage columns with loads stored in vertical racks within the columns. A vertical lift mechanism moves up and down each column to access any storage location. VLMs offer higher density storage in limited floor space.

New Applications and Trends:

With advancements in robotics, sensing, and control technologies, AS/RS solutions keep evolving. Some emerging applications and trends include:

– Mobile AS/RS: Autonomous robot mobile units move inventory between stationary ARS and picking areas for multi-level fulfillment.

– Micro-fulfillment: Combination of AS/RS, robotics, and software to enable very high-density fulfillment of e-commerce orders in smaller footprints.

– Collaborative robots: Cobots or collaborative robots safely work alongside humans for applications like case-picking to augment personnel.

– AI and machine learning: Algorithms optimize storage assignments, routing, and resource allocation based on demand patterns learned over time.

– Integrated control systems: Common controls coordinate WMS, MHE, conveyors, sorters for fully autonomous distribution environments.

– Modular systems: Standardized, pre-assembled components fast-track implementation and adapt to gradual expansion needs.

Automated storage and retrieval has revolutionized warehouse management by streamlining material flows with greater accuracy and efficiency. AS/RS will remain a critical part of warehouses, focusing more on adaptability, human-robot collaboration, and smart control systems to unlock next-level productivity andservice levels. Their widespread adoption across industries will continue to modernize supply chain operations globally.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it